At Energy Solution, we provide power generation systems that achieve both effective use of energy resources and reduction of environmental impact. We use the technology and knowledge we have cultivated to respond to the diversifying power needs of each country, and our mission is to build a sustainable future. We will continue to contribute as a global leader in shaping the future of global society through advanced energy technology.

The role of design and development engineers is to reflect Hitachi's technological capabilities in products and to bring new value to the world by creating new products. They provide estimates and product designs based on customer requests and manage the product through to completion.

Production Engineering Engineers are responsible for expanding production volume and improving production efficiency from a technical perspective. They plan overseas production bases (new construction & capacity expansion), introduce the latest equipment, and build efficient production systems through production process reform.

Quality assurance engineers are responsible for one of the most important issues for manufacturers: quality assurance. As the cornerstone of product reliability, they conduct thorough technical verification to ensure that delivered products and systems reliably meet the required functions, performance, durability, etc.

We provide optimal solutions to customer needs through our technical expertise. We play an important role in responding to customers, involving members from various fields such as design, manufacturing, production engineering, quality assurance, and human resources.

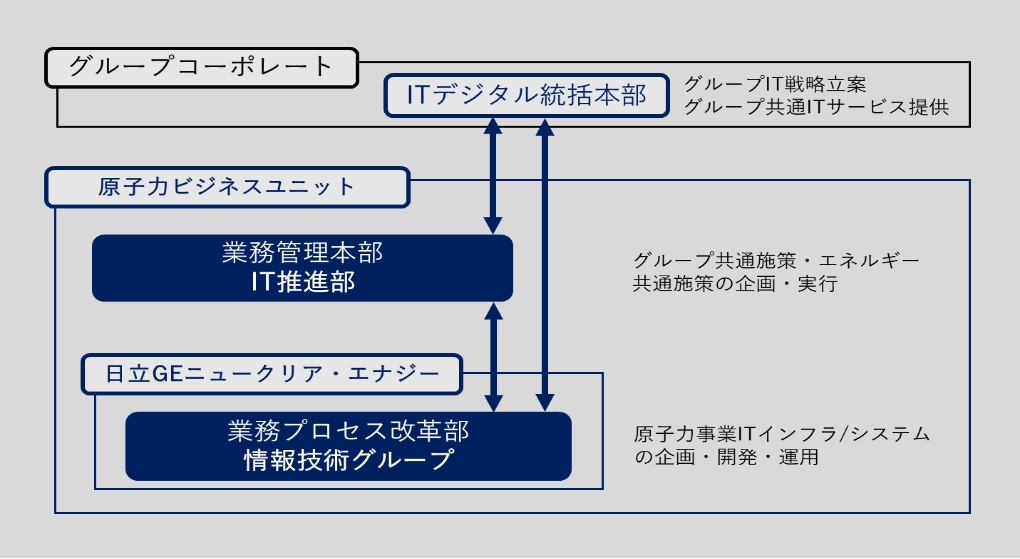

In the field of internal IT systems for the nuclear power and energy business, we will contribute to the business through the use of IT and digital technology.

üEPlanning, designing and implementing IT strategy

üEBuild, operate and maintain business applications

üEBuild, operate and maintain IT infrastructure and platforms

üEUser support and consulting

üEIT Governance, Security Management and Auditing

Nuclear power generation, which does not emit CO2 during electricity production, serves as a major pillar of the Hitachi Group's environmental initiatives, particularly in preventing global warming. To achieve carbon neutrality and ensure stable energy supply, Hitachi's nuclear business is committed to contributing to society through the development of advanced proprietary technologies and products. This includes improving the safety of existing nuclear power plants in Japan, expanding small modular reactors (SMRs) with growing global demand, developing next-generation and fast reactors, and decommissioning the Fukushima Daiichi Nuclear Power Plant. By leveraging the Hitachi Group's comprehensive capabilities, we are creating reliable manufacturing and services that will help shape the future of our planet.

In the field of nuclear fusion and particle accelerators, we have been designing and manufacturing experimental equipment for research and development in the fields of nuclear fusion and particle accelerators, which are mainly promoted as national projects, for over half a century since the beginning of research in the 1950s, and as a comprehensive electrical manufacturer, we have contributed to the development of these fields. We are committed to contributing to the development of science and the social implementation of technology toward the realization of a sustainable society from the perspective of manufacturing, combining the reliability based on our deep experience with the advanced nature that gives shape to the ideas of our customers, the researchers.

Hydroelectric power generation converts the potential energy of water into kinetic energy to turn a water turbine, which in turn produces electricity in a generator connected to the turbine. Because it uses water from rivers, it does not use fossil fuels such as coal, oil, or natural gas, and it does not emit carbon dioxide, thus contributing to the realization of a carbon-neutral society. Hitachi has a history of more than 100 years in the field of hydropower, beginning in 1912 with the operation of a horizontal-shaft Pelton turbine and generator at the Mine-no-sawa Mine.

In 2011, it integrated its hydropower business with Mitsubishi Electric Corporation and Mitsubishi Heavy Industries, Ltd. to form Hitachi Mitsubishi Hydro Corporation. Going forward, Hitachi Mitsubishi Hydro Corporation will continue to contribute to the stable supply of electricity by providing hydropower generation solutions.

We are developing IT-based solutions to meet the various needs and challenges faced by employees in the nuclear and power business, and we are creating and operating an environment that enables employees to perform at their best. For example, we are working to strengthen our management base and streamline operations through the use of IT, create a safe working environment by taking measures to address safety risks, and improve employee engagement through work style reforms.

The Green Energy & Mobility Division provides customers with a full range of product lifecycle services, from order receipt to after-sales service, for products such as nuclear, wind, and solar power generation systems, as well as power distribution systems. We are actively implementing cutting-edge production and manufacturing technologies to reduce CO2 emissions and achieve zero waste in our production facilities. We will also develop high-quality production technology and production equipment with high environmental value to achieve a circular economy and carbon neutrality. In addition, we will promote the digitalization of production processes and strive to improve production efficiency by enhancing the resilience of our production base and ensuring stable supply. We will realize our customers' needs through high-quality, low-cost "monozukuri" with high environmental value.

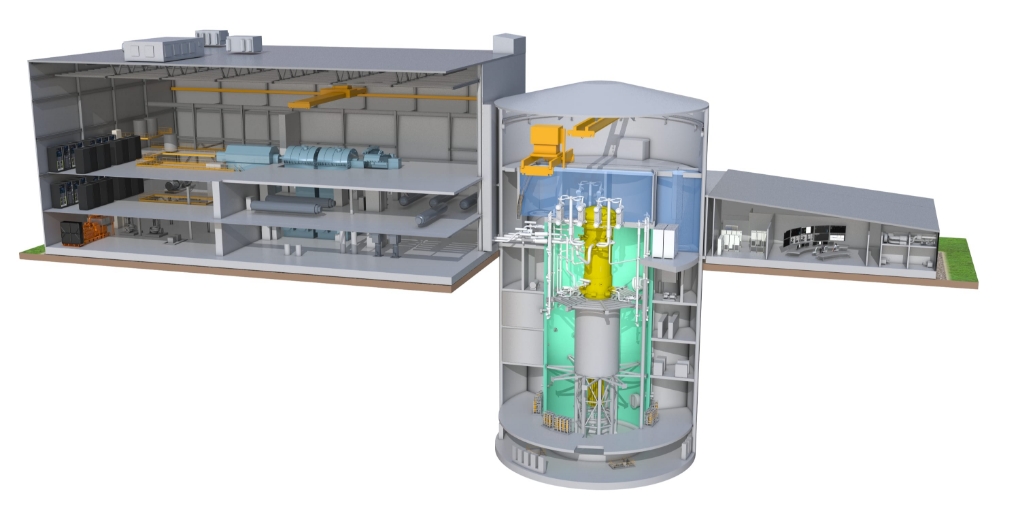

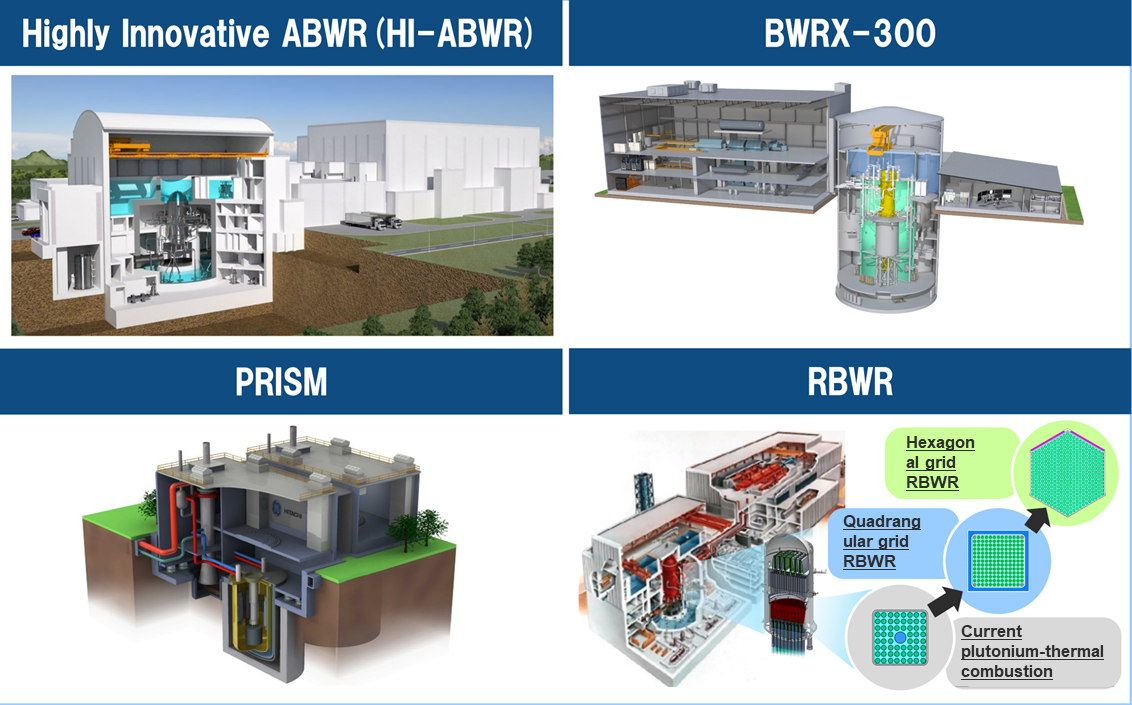

We are developing and promoting the SMR (BWRX-300), a compact light water reactor that will solve future energy problems, through international cooperation with our partner company, GE Vernova Hitachi Nuclear Energy of the United States, and other companies. The SMR is attracting attention as a next-generation reactor that will enable construction while maintaining safety and reducing power generation costs, leading to improved market competitiveness. The BWRX-300 has been selected as the reactor type for Ontario Power Generation, the provincial utility of Ontario, Canada, and we plan to obtain construction approval in Canada in 2025 with the goal of completing construction in 2029. We are also working with GE Vernova Hitachi Nuclear Energy to expand sales of the ABWR, which has a proven track record.

Since the accident at the Fukushima Daiichi nuclear power plant in March 2011, all BWR nuclear power plants in Japan have been shut down, and in order to restart, they must comply with new regulatory standards. Hitachi is contributing to the early restart of BWR plants by supporting the review of the new regulatory standards and by developing and modifying safety equipment. Hitachi has also participated in the international joint development of the ABWR, which offers high levels of safety, operability, and economic efficiency, and has constructed the first units of this type, namely Units 6 and 7 of the Kashiwazaki-Kariwa Nuclear Power Station of Tokyo Electric Power Company Holdings, Inc. and Units 5 of the Hamaoka Nuclear Power Station of Chubu Electric Power Co. and Unit 2 of the Shika Nuclear Power Station of Hokuriku Electric Power Co. We are currently constructing Shimane Unit 3 for Chugoku Electric Power Co., Inc., Ohma Unit 1 for J-Power Co., Inc. and Higashidori Unit 1 for Tokyo Electric Power Company Holdings, Inc. using advanced construction technologies based on design optimization, standardization and extensive construction experience.

To ensure the sustainable use of nuclear energy, it is essential to complete the nuclear fuel cycle by storing and reprocessing spent fuel. In the field of reprocessing, we are working on the construction and trial operation of the commercial spent fuel reprocessing plant (JNFL) in Rokkasho Village, Aomori Prefecture. In addition, we are participating in the construction of facilities for the interim storage of spent nuclear fuel, supplying transportation equipment, etc., and developing and manufacturing metal containers for use in both transportation and storage. In addition, we are promoting the development of fast reactors and next-generation fuel cycles that will achieve effective utilization of resources, reduction in the volume of radioactive waste, reduction in toxicity, etc.

In order to meet the needs of countries that are building or introducing new nuclear power plants, we are working on 1) the practical application of the Large Innovative Light Water Reactor (HI-ABWR), which is based on the ABWR and incorporates new safety mechanisms to further improve safety, operability and economic efficiency; 2) the BWRX-300, a compact light water reactor that offers a flexible configuration that responds to the characteristics of the local area while maintaining high safety and economic efficiency, ćB the small fast reactor PRISM, which achieves a high level of safety through the use of metallic fuel and passive safety systems based on air cooling, and ćC the Light Water Cooled Fast Reactor (RBWR), which enables the recycling of transuranium elements (TRUs) such as plutonium and minor actinides (MA) as fuel in a water-cooled reactor.

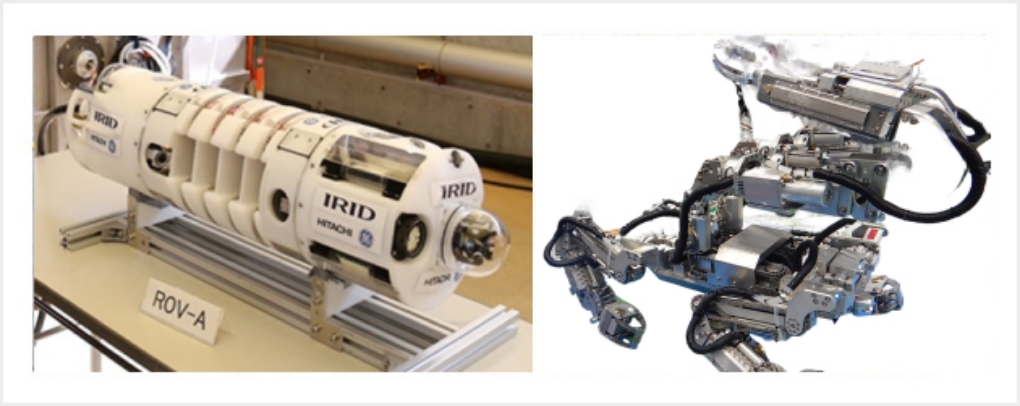

One of the technical issues to be resolved in order to complete the decommissioning of the Fukushima Daiichi Nuclear Power Station is the removal of the nuclear fuel remaining in the reactor buildings. We are considering various methods to facilitate the work required to remove the nuclear fuel, such as surveying the reactor buildings, decontamination, repair, and environmental improvement. The use of remote-controlled robots is effective for work in radiation environments that are difficult for humans to access, and we will continue to steadily develop remote-controlled robots and removal methods for removing nuclear fuel and contribute to the completion of the decommissioning of the Fukushima Daiichi Nuclear Power Plant (Fukushima reconstruction) as soon as possible.

Nuclear power plants, thermal power plants, and other power plants all consist of mechanical equipment and parts, such as heat exchangers, pumps, compressors, diesel engines, piping, and valves. The nuclear reactor pressure vessel, which is unique to nuclear power plants, has equipment that separates and dries the steam inside, as well as a mechanism that inserts and removes the control rods that control the nuclear reactions. These are made up of a wide range of technical fields, including mechanical dynamics (mechanics, materials, fluids and heat), vibration, mechanical elements, machining and processing, and measurement and control.

In nuclear power plants, a variety of mechatronics products that operate automatically or remotely are used to save labor during periodic inspections, to inspect and repair the reactor itself and its peripheral equipment, and to reduce workers' exposure to radiation. Knowledge in mechanical engineering, electrical engineering, electronics engineering, materials engineering, etc., is used in the development and design of fuel handling equipment, control rod drive mechanism replacement equipment, and robots for surveying the interior of the Fukushima Daiichi Nuclear Power Plant, and the products manufactured are used in nuclear power plants.

Based on the latest knowledge and fundamental technologies from Japan and overseas, we propose optimal material composition and water chemistry management for the design and problems of nuclear power plants as a whole, contributing to the realization of highly reliable and economical plants. We also actively collaborate with research institutions that have nuclear materials and water chemistry technology to expand data and provide theoretical support. In recent years, we have worked to maintain plant integrity by studying the introduction of the first domestic use of precious metal injection into the primary cooling water of operating nuclear reactors.

I&C is the nervous system of a power plant. By properly configuring sensors, transmission lines, and control systems, we maintain the safety of the power plant and contribute to highly efficient operation. In addition, power is needed to operate the various types of equipment in the power plant, and the design of the power supply system within the power plant is also an important design task. As a technology that "connects" things, people from a wide range of fields, including not only the nuclear field, but also information, control, electrical, and ergonomics, are working together.

We are continuously promoting the improvement of engineers' skills to produce products for nuclear power generation that contribute to high safety and carbon neutrality. At the 2022 WorldSkills Competition, our engineers won a gold medal in the welding category.

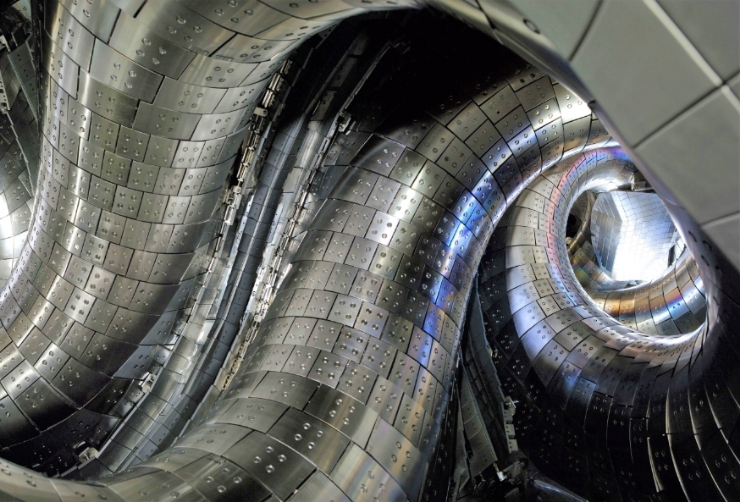

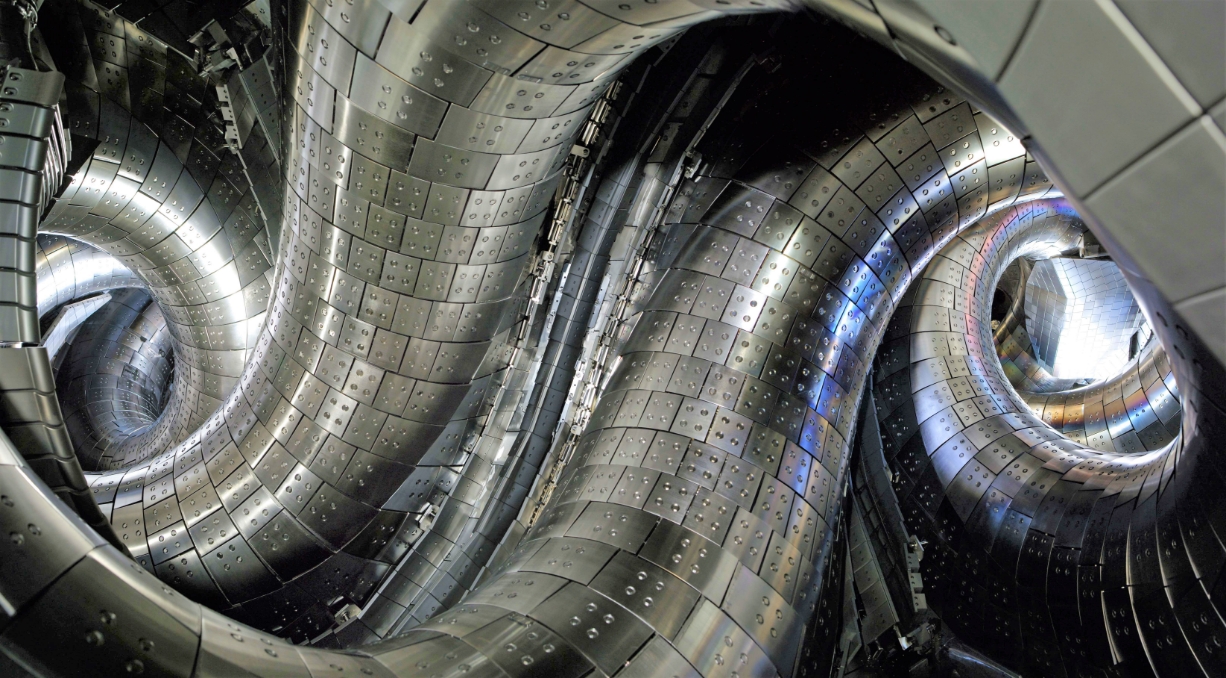

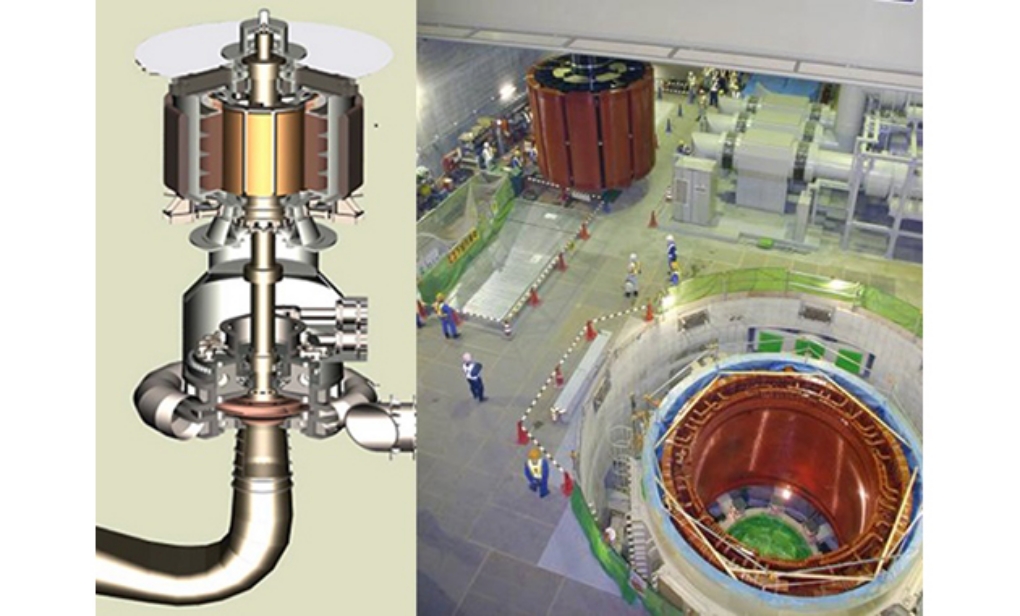

Nuclear fusion research is being promoted as one of the leading candidates for a new, carbon-neutral energy source and is attracting attention through the Cabinet Office's Fusion Energy Innovation Strategy. We are contributing to the promotion of cutting-edge research by designing and manufacturing equipment for experimental facilities such as the International Thermonuclear Experimental Reactor (ITER), JT-60SA (currently the Quantum Science and Technology Research Development Organization (QST)), and LHD (National Institute for Fusion Science (NIFS)), and supporting their operation and maintenance. We are also participating in technical studies as a member of the design team for the "prototype reactor" currently being considered by an all-Japan system, and we are also considering collaboration with startup companies aiming for early power generation with private funding.

Nuclear Fusion Experimental Facility (Left: Inside the LHD plasma vacuum vessel (Photo provided by NIFS) / Right: Neutral beam injector power supply test facility for ITER)

We work on the technological development of particle accelerators and contribute to the development of advanced science. In particular, we are participating in large-scale accelerator projects (such as "J-PARC"*(JAEA, KEK) and "Super-KEKB" (KEK)) and working on the technological development of key components such as electromagnets and accelerating cavities. We are also involved in the production of superconducting magnets for the "LHC High Luminosity Upgrade" at the European Organization for Nuclear Research (CERN) (KEK).

*J-PARC: Japan Atomic Energy Agency (JAEA) and Inter-University Research Institute Corporation. High Energy Accelerator Research Organization (KEK).

Image: Research accelerator (CERN LHC high-brightness upgrade superconducting magnet (total length 7m))

Based on the electrical equipment manufacturing technology we have cultivated through the production of generators and transformers, we design and manufacture a variety of experimental equipment for research and development in the fields of nuclear fusion and accelerators. These technologies are applied to superconductivity and cryogenic technology, ultra-high voltage technology, ultra-high vacuum technology, and the production of large structures, and by combining them with system technology, we have contributed to the development of these fields as a comprehensive electrical manufacturer. In addition, in cooperation with the Research and Development Department, we are promoting the in-house development of distinctive technologies such as design and manufacturing technology for arbitrary shapes and high-precision magnetic fields, high-current ion sources and beam transport technology, and high-temperature superconducting wires. These technologies are also being applied and developed in the healthcare business, such as magnetic resonance imaging (MRI) and particle beam therapy (PBT).

* If you are interested in superconducting products for consumer applications, please also see the Hitachi High-Tech page.

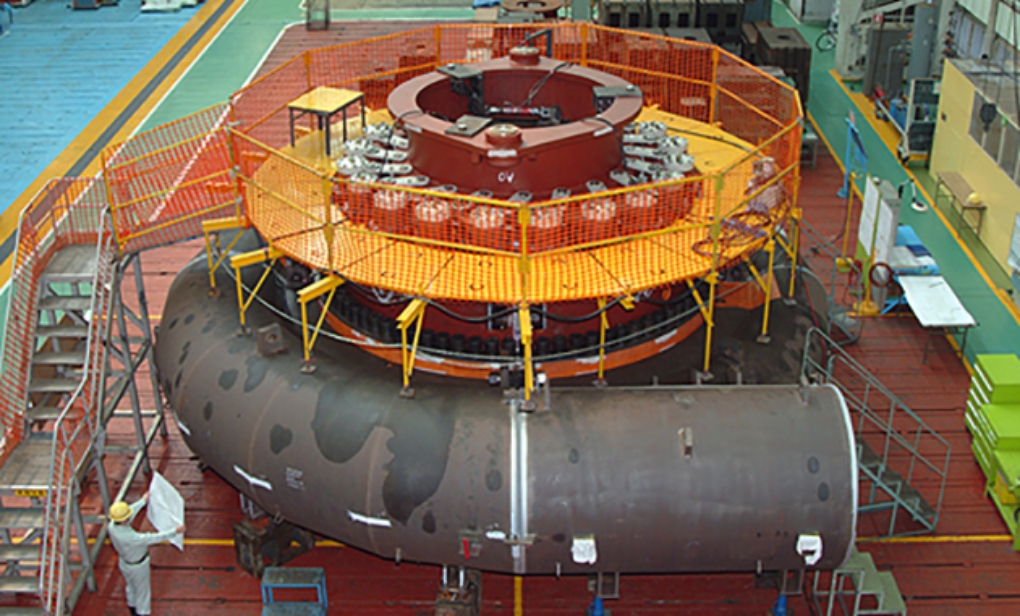

The water turbine is the driving force behind hydroelectric power generation. We plan, develop, design, manufacture, install and test water turbines with the high reliability backed by our experience. By participating in the design of new power plants from the outset, we help ensure that hydroelectric power plants are optimized for each site. Hitachi's hydroelectric power plants are individually optimized for each power plant to make effective use of water resources. The collective wisdom of our engineers contributes to the environment.

Pumped storage power generation contributes to the generation and storage of electricity through power generation and pumping. In order to achieve economic benefits, there is a trend toward higher head and higher speed. The reliability and stability of high-head pumped storage power generation is ensured by the steady accumulation of pumped storage power generation technologies and the effective combination of these technologies.

Variable-speed pumped storage power generation contributes to the stabilization of power grids through its high-speed, large-capacity, effective power regulation capabilities, and it also contributes to the reduction of greenhouse gas emissions by reducing the need for power regulation by thermal power generation. In particular, it is attracting attention as a large-scale energy storage system in response to the increase in renewable energy sources, and there are plans for new installations overseas and variable-speed conversion of existing plants in Japan. Based on our track record of implementing projects in Japan, we are working on projects in Japan and overseas in cooperation with relevant departments.

Repowering of Existing Hydroelectric Plants. To make effective use of existing dam facilities and improve power generation efficiency, power plants that have been in operation for more than 30 years are being upgraded with new equipment. We are working not only to improve the characteristics of our own equipment, but also those of other companies. By combining existing facilities with equipment developed using the latest technology, new hydroelectric power is being generated around the world.

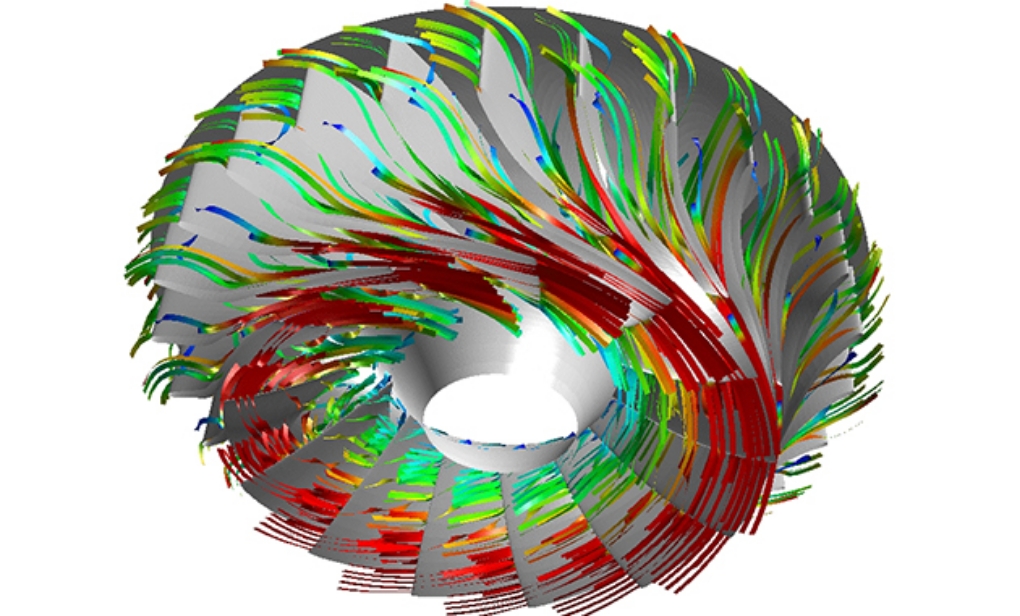

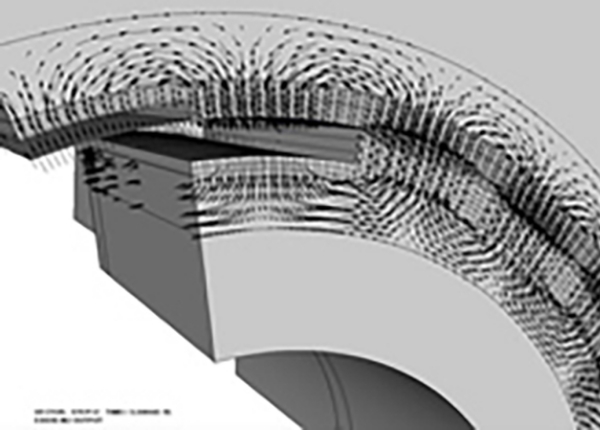

Hydroelectric power plants are designed to be optimized for each site. We use fluid simulation and measurement technology to find the optimal shape, and also conduct verification experiments to establish highly reliable operation. We share the problems of each power plant with the power plant owner and try to solve them through analysis and experimentation.

A regulator that controls the operation of the water turbine. A hybrid controller that combines mechanical and electrical systems to support optimal operation of the water turbine. It works in conjunction with other controllers to help ensure a stable power supply.

A generator that is directly connected to the water turbine and drives it to produce electricity. We develop, design, manufacture, install and test generators with single unit outputs ranging from several thousand kW to several hundred thousand kW. We also design and supply generators that combine the functions of a generator driven by a water turbine and an electric motor that drives a pump by reversing the direction of the water turbine, as well as variable-speed generators that can be operated by varying the speed of rotation. Responding to market demands for increased capacity and improved efficiency, and utilizing the technological capabilities we have cultivated in the highly competitive global market, Hitachi generators continue to evolve.

Hitachi continues to supply high-voltage, large-capacity synchronous motors that drive pumps, compressors, and fans used in various industries in response to customer needs. We are also focusing on the supply and maintenance of synchronous power conditioning machines for business use and motor-generator sets for nuclear fusion power sources, which utilize the technology of large-capacity vertical-shaft synchronous generators for hydropower and large-capacity synchronous motors for industrial use.

In order to make effective use of water resources, we are working to increase the efficiency of water turbines by making full use of fluid simulation and experimental measurement technology. In addition to increasing the efficiency of pump turbines for pumped storage power generation, which contributes to the efficiency and stability of power system operation, we are also working on the development of variable-speed pump turbine runners.

The runner is the heart of a water turbine. We continue to provide runners with new shapes that can be applied to unique locations and a wide range of operating conditions. We use 3D CAD/CAM digital engineering technology to develop new-shape runners consisting of complex 3D curved surfaces.

Pumped storage power generation motors are reversible energy conversion devices that can be used as motors to pump water up to the upper dam during periods of low power demand, such as at night, and then store it as large amounts of potential energy, and then be used as generators to supply power to the grid during periods of high power demand. With the recent trend toward higher speeds and capacities, there is a need for designs that improve the cooling characteristics of power generation motors as their capacity increases, rotors that can withstand high centrifugal forces, and highly reliable, high-speed, high-surface-pressure bearings. We develop and design using advanced electromagnetic field, stress, thermal and fluid analysis technology.

The variable-speed pumped-storage power generation system is a new pumped-storage power generation system that can transfer power to and from the power grid even when the speed of the generator motor changes. In addition to balancing the power supply between day and night, it also has excellent functions such as grid frequency control during operation, and contributes to improving grid stability by being able to transfer power to and from the grid at high speed using the inertial energy of the rotating parts. This is a system product that integrates generator technology and power electronics technology at a high level, and new materials, structures, and manufacturing methods that are different from conventional generator motors have been developed and applied to the variable-speed generator motors used in this system.

We are contributing to the effective utilization of hydroelectric power by actively working on repowering projects in the United States and other countries that have already adopted advanced hydroelectric power generation systems, as well as new projects in countries around the world. We are also working with overseas partners to provide highly reliable products in the procurement and manufacture of parts.

Hydraulic power generation equipment, high-head pumped storage power generation equipment, water turbine control equipment, fluid simulation, hydraulic power laboratory, commercial power generators, variable-speed power generation motors, large-scale industrial synchronous motors, electric generators for nuclear fusion power supply, electromagnetic field analysis.

Hitachi has supplied a 525 MVA/464 MW air-cooled generator-motor, the world's largest single unit capacity generator-motor, and a 30 MW thyristor starter that makes full use of the latest digital control technology. In recent years, there has been a growing trend to reevaluate hydroelectric power as a clean energy source that does not produce carbon dioxide, and the large-capacity technology for generator motors and digital control technology for thyristor starters developed at the Kannagawa Plant are attracting attention as technologies that contribute to the global environment.

The variable-speed pumped storage power generation system, which contributes to load leveling of power demand and frequency stabilization of power systems, is also expected to play a role as an energy storage device in response to sudden increases in power demand and emergency situations. The Komarugawa Power Plant, which has developed a large-capacity, high-speed, variable-speed pumped-storage power generation system, can provide power equivalent to that of a nuclear power plant in just 2.5 minutes from standstill. It is becoming increasingly important as renewable energy sources such as solar and wind power are promoted in an effort to curb carbon dioxide emissions.

The Toshka Development Project, a central initiative in Egypt's desert greening efforts, aims to transform 225,000 hectares of desert (an area equivalent to Tokyo) into agricultural land and establish settlements for 3 million people. This ambitious project involves constructing an extensive irrigation canal network spanning 240 kilometers and massive pump stations. Hitachi played a pivotal role in the pump station project, taking responsibility for the mechanical and electrical system design and equipment supply. Our division manufactured and delivered 21 units of 12MW synchronous motors to drive the pumps in these massive pump stations.

In order for companies to increase their competitiveness, it is important to build business processes that can adapt to the rapidly changing business environment. In this business area, we are promoting digital transformation (DX) in the Green Energy & Mobility Sector. For example, we are working to improve our ability to make proposals and increase profitability by introducing sales support tools and centralizing the management of customers in Japan and overseas. In addition, the coronavirus pandemic has also led to changes in work styles, and by developing communication tools and usage guidelines, and providing a comfortable work-from-home environment, we are helping to increase employee motivation and productivity.

In this Business Field, we promote the digital transformation (DX) of the nuclear power and energy business going forward. For example, we are promoting the planning, design, construction, and implementation of digital foundations for core business systems (ERP*1), project management, and engineering support, as well as the conception and design of digital twins and customer collaboration systems. In addition, we promote the use of the latest technologies such as generative AI and metaverse in collaboration with various departments within and outside the Company.

The value chain of our business consists of operations such as sales, projects, design, procurement, manufacturing, construction, quality assurance, procurement, planning, and finance, and each of these operations has IT systems to perform these tasks, as well as IT infrastructure to operate the IT systems. The stable operation of IT systems and IT infrastructure is essential for the smooth running of operations. In this business, we plan, design, develop, operate and maintain IT systems and infrastructure, and contribute to the business continuity of the nuclear energy business from an IT perspective. At the same time, we carry out reform activities such as migration, consolidation, and elimination of existing IT systems, and contribute to the reduction of IT costs and shortening of working hours by standardizing operations.

In this business area, we control information security policies and measures for each BU and all Group companies in the nuclear and energy business. We conduct information security audits to verify that operations are conducted in accordance with internal information security rules, and we also create rules in accordance with future business structures that utilize IoT (*2) and SaaS (*3). We also plan BCP (*4) training and play a role in strengthening the company's ability to respond to information security incidents. Through these activities, we contribute to the business continuity of the nuclear and energy business.

*1 ERP: Enterprise Resource Planning

*2 Internet of Things

*3 Software as a Service

*4 Business Continuity Planning

In the internal IT system department, you can use the following skills. These skills will improve as you work, so it is not a problem if you do not have them now. Let's improve our skills together.

In project activities, there will be frequent meetings and you will interact with people from different departments. By listening to the opinions of the people involved and making suggestions that meet the needs of the other party, you can carry out your work smoothly.

If you do not come up with appropriate solutions to the needs and problems within the company, you will not be able to achieve the desired results. By using frameworks to organize cause-and-effect relationships, classify problems, and subdivide them, you can plan effective interventions.

Since work is done in teams, everyone must have the same goals and work to meet deadlines. Through risk management, schedule management, etc., you can maintain team performance and achieve results as planned.

By understanding the IT background knowledge, such as IT system updates, you can find problems and solutions faster.

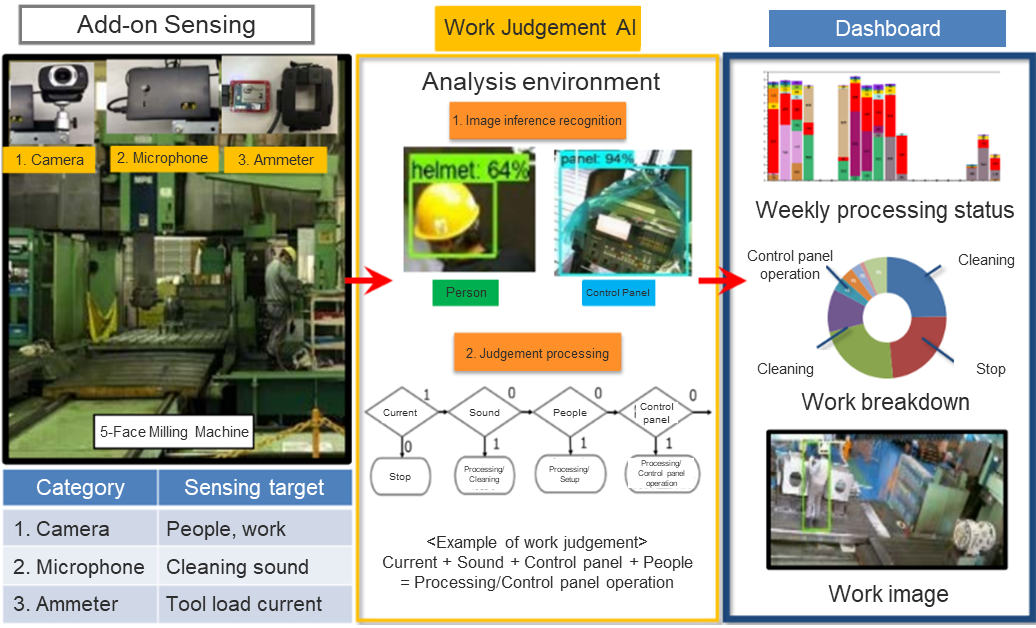

In the manufacturing industry, we used the data analytics environment of the Lumada IoT platform to analyze production operations and address the issue of delayed work compared to the plan. Specifically, we visualized the processing status each week on a dashboard by (1) arranging IoT sensors, (2) classifying work using machine learning, and (3) extracting critical data through statistical data analysis. This reduced the amount of time wasted when machines were not in operation, and contributed to shortening production lead time.

In addition, we are promoting the activities of the Nuclear Digitalized Asset Center (N-DAC), which integrates and aggregates various forms of digital data, such as design data including books, drawings, CAD data, and various attribute information, and point cloud data obtained by measuring the structures of nuclear power plants using a 3D laser scanner, and uses them in design work. By enabling the visualization and use of data from design to construction, we aim to improve the productivity of design work and promote work style reform. In addition, we are promoting digitalization for preventive maintenance and decommissioning, with the aim of advancing the entire nuclear power business.

We are contributing to the efficiency of project management operations by developing a dynamic management tool that visualizes the progress of building permits and construction projects using the application development environment of Microsoft 365, which is used by all Hitachi Group companies. We also developed a tool for confirming email recipients using Microsoft 365 profile photos, which has helped prevent information security incidents by greatly reducing the number of email transmission errors. In addition, we are promoting the expansion of tool functions to eliminate the use of emails with password-protected ZIP attachments (commonly known as PPAP*2), which is a measure for the entire Hitachi Group.

In addition, for paper-based tasks that require employees to come into the office to stamp and sign documents, we are using cloud services and an internal circulation system to reduce costs by going paperless and enabling approval work to be done from home, thereby contributing to the realization of a flexible way of working.

*2 PPAP: Password-protected ZIP file will be sent, Password will be sent, Angoka (Encryption) Protocol (Protocol)

We develop production equipment and manufacturing tools to produce high-quality products quickly and at low cost. We are working to improve the efficiency of production operations by developing our own production equipment using IoT technology (mechatronics, electrical and control design) and incorporating CAD and CAM technology. In addition, manufacturing requires continuous improvement in productivity and cost reduction. We are also working to reform production processes by analyzing current operations and using IE (Industry Engineering) to create more efficient processes. We are working to achieve GX (green transformation) and DX (digital transformation) in order to compete in the global environment.

To reduce CO2 emissions from production at our plants, we plan to introduce energy-saving and renewable energy equipment and utilize energy management systems, etc., with the goal of achieving carbon neutrality by 2030. In addition, we are working to achieve zero landfill waste by effectively utilizing waste materials such as plastics generated in production as raw materials and fuels, and are working toward the realization of a sustainable resource cycle and a decarbonized society.

In the production of energy equipment, which is a social infrastructure that requires a high level of reliability, it is essential that the basic facilities (electricity, water, communications, etc.) and processing and transportation equipment (machine tools, presses, cranes, etc.) of the production plant always operate at a high level of precision and normally. We are working to improve environmental value and resilience by responding to the trend of the times with greening and digitalization, while implementing the development, introduction, management, and maintenance of the core facilities of these production plants with a thorough system.