We are a company that was spun off from Hitachi, Ltd. in April 2019 and is responsible for the large-scale industrial equipment business. We develop medium- and large-scale motors, UPSs, inverters, compressors, pumps, etc. globally and promote the social innovation business with "digital green innovation" as its core. We continue to take on innovative challenges by providing new solutions while reducing environmental impact. Why don't you join us in taking on exciting challenges like creating solutions that don't exist in the world yet and making the impossible possible?

The role of design and development engineers is to translate evolving technology into products that bring new value to the world. They are responsible for the development and commercialization of industrial equipment such as motors, inverters, compressors, and pumps in each Division.

They are responsible for thorough technical verification to ensure that delivered products and systems reliably meet the required functions, performance, durability, etc., and for proactive management of loss cost reduction through business risk review.

We play an important role in responding to customer needs by proposing solutions based on our technical knowledge and involving people from various departments such as design, manufacturing, production engineering, quality assurance, and human resources.

We play a role in expanding production volume and improving production efficiency from a technical perspective. We realize optimal production and product development through advanced manufacturing technology.

We apply various diagnostic technologies to equipment already delivered, and are responsible for maintenance work, including early detection of deterioration, maintaining functionality, preventive maintenance, extending the life of equipment, and upgrading functionality to save energy and labor.

We plan and organize projects, including construction planning, procurement of materials, coordination with construction companies, negotiations with customers, schedule management, and supervision of work as equipment is delivered and installed on site based on design and planning.

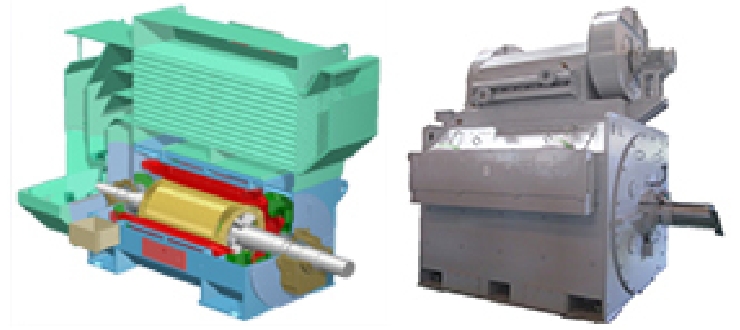

The Drive Systems Division is involved in the design, development, production and after-sales service of a wide range of electrical equipment. The division is made up of the Production Division in the Hitachi area and the Business Planning Division in the Tokyo area. The division is contributing to the improvement of the value of customers, society and the environment by polishing the electric motor business, which is one of Hitachi's founding products and has a history of over 100 years, using the latest materials technology and technology, and by sending products that meet the needs of a wide range of customers, both in Japan and overseas, to the world.

Hitachi's founding product, the electric motor, has been used in a wide range of fields, including power generation, industry, and transportation, for over 100 years, supported by a tradition of technology. In recent years, we have developed diagnostic technology that incorporates IoT and digital technology to predict when equipment needs to be replaced, providing value throughout the entire product lifecycle. We are using Hitachi's Lumada solutions to strengthen processes from design to operation and maintenance with digital innovation.

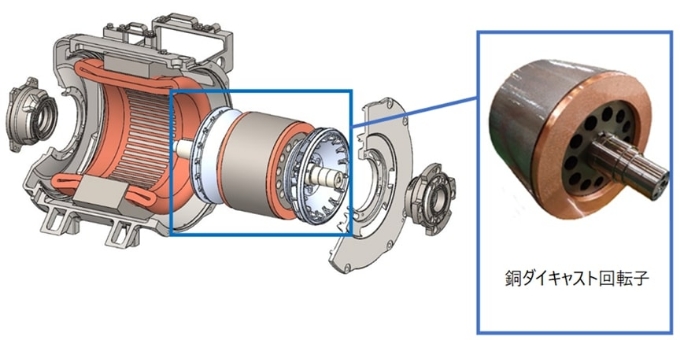

Electric motors for high-speed railway vehicles such as Shinkansen trains are being commercialized with cutting-edge technology that offers high efficiency, compactness, lightness, and low maintenance. The railway business is positioned as a growth area due to the increasing awareness of environmental issues, and the development of next-generation electric motors is also underway. In addition, technology for industrial and railway vehicles is also being applied to generators and traction motors for mining dump trucks, enabling stable operation even in harsh environments. We will continue to actively work on the electrification of mobility in the future.

As the importance of electricity increases, Hitachi's private power generation equipment provides a highly reliable power supply in the event of power outages or natural disasters, and supports social infrastructure. In addition to emergency power generation equipment, we also provide cogeneration power generation systems for the purpose of energy conservation and CO2 reduction in factories and facilities. Engineers in the fields of electricity, mechanics, control, and project management are active in the development and management of these facilities, and we are continuing to recruit personnel.

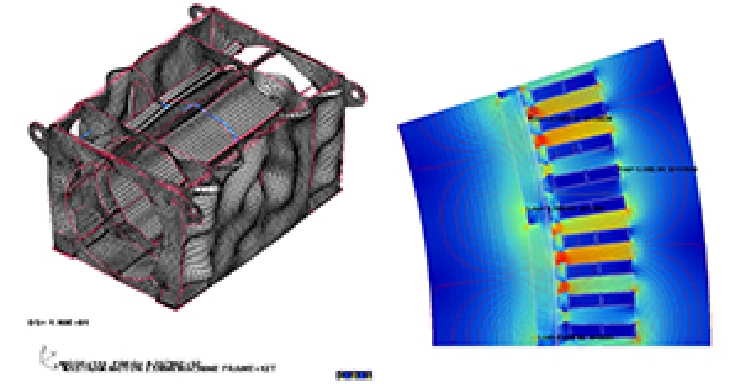

Since the founding of Hitachi, we have continued to supply high-voltage, high-capacity electric motors that drive compressors, pumps, and fans used in various industries, as well as electric motors for railway vehicles, and we are developing products that meet the changing needs of the times. Since the development items cover a wide range of areas, including temperature, vibration, and noise, we are developing products by bringing together teamwork and making full use of various simulations.

AC variable-speed drive systems have realized improved productivity and quality, as well as reduced maintenance and energy consumption in steel plants, thanks to advances in power electronics and control technology. Hitachi is contributing to the efficiency of steel plants by manufacturing and supplying high-performance, high-quality, highly reliable AC variable-speed motors based on the extensive experience it has gained in rolling mill drives.

Ultra-large dump trucks, which are used to transport ore excavated from mines, have a gross vehicle weight of 300 to 500 tons. They are driven by electric motors that are controlled by inverters. We develop and commercialize the generators and motors used in these vehicles.

We have commercialized copper die-cast rotors for railway vehicle traction motors for the first time in the world (according to our research), and have achieved a reduction in mass. By adding lightweight technology to the high-efficiency technology that Hitachi Industrial Products has traditionally possessed, we will contribute to further power savings and reduced environmental impact in railway vehicles in the future.

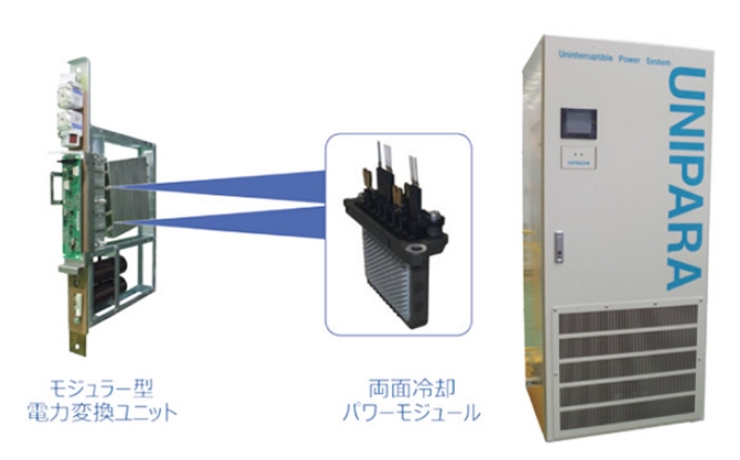

The Power Electronics Division is essential for reducing CO2 emissions and improving energy efficiency, and is playing an active role in various fields as a key technology for a sustainable society. We develop and provide uninterruptible power supplies (UPS) for important facilities that operate 24 hours a day, industrial equipment, motor inverters for the electric drive of large dump trucks, and grid-connected inverters for smart grids. We support society's energy conservation and use of renewable energy by applying semiconductor device technology, high-voltage insulation, and energy storage system technology to products that require high voltage, high power, and complex control technology.

As the shift to EVs progresses toward achieving carbon neutrality, the urgent need to expand charging infrastructure is increasing. In particular, as the demand for rapid charging of large commercial EVs increases, Hitachi Industrial Products' high-capacity, ultra-rapid charging multi-port EV chargers are designed to meet this need. They are compliant with the next-generation CHAdeMO 3.1 (ChaoJi 2) standard, and can connect up to 20 ports to a single power source, and are also compatible with V2X* and contribute to power stabilization.

*Vehicle To X (X: Grid, Building, etc.)

A function that supplies the power stored in the batteries of electric vehicles to power distribution systems and buildings

We provide high-voltage direct inverters that directly drive high-voltage motors, and use multiple transformers and multi-stage series inverters to output high-efficiency variable-frequency sinusoidal AC voltage. This contributes to improved controllability and energy conservation. In addition, we have achieved a smaller, lighter design through rational structural design using simulation technology such as new materials, new construction methods, and electromagnetic field and thermal flow analysis. We will continue to develop drive systems with high functionality, high performance, and high reliability.

As the electrification of large dump trucks progresses, saving energy and labor, we are providing electric drive systems using high-voltage, high-capacity inverters to realize high-performance electric drive trucks. In addition to basic driving, we are also adopting design technology that can cope with severe environments such as high temperatures, low temperatures, and high vibration, as well as advanced motor drive control that includes vehicle control. Furthermore, we are providing higher value to users by increasing capacity, advancing control technology, and responding to new applications.

Uninterruptible Power Supply (UPS) is widely used to support information and communication systems, which are the foundation of the information society. The demand for UPS is increasing year by year, and there is a demand for reliability of continuous power supply 24 hours a day, 365 days a year, low running costs, energy saving, compactness, lightness, expandability, etc. In particular, the UNIPARA technology is used as the standard for UPS for data centers, and we provide optimal systems that meet customer needs, from small capacity to large capacity systems. We also handle product design, production, and planning in an integrated manner to meet diverse market needs.

In Japan, the introduction of renewable energy sources such as solar and wind power is being promoted as a measure to protect the global environment. We provide power conditioners (PCS) that stably supply the direct current power from solar panels and the alternating current power with fluctuating frequency from wind power generation to the power transmission system. In order to minimize the impact of fluctuations in power generation on the stability of the power system, we are working with internal and external research institutions and overseas bases to improve performance and contribute to the promotion of the spread of renewable energy.

We provide the HF-W series of industrial computers, which meet the needs of social systems, semiconductor manufacturing equipment, medical equipment, etc., for long-term stable operation and long-term supply. These are equipped with RAS functions that improve reliability, availability, and maintainability. In addition, we also provide the HF-W/IoT series, which is equipped with edge computing functions that enable real-time data collection and analysis to meet the needs of the IoT era, and seamlessly links OT and IT.

In the Mechanical Systems/Mechatronics Division, we design and manufacture industrial machinery such as compressors, pumps and blowers that control water, air and gas, as well as building logistics systems for plants. We also focus on research and development of next-generation products, such as disaster prevention and energy-saving products, and testing machines for disaster response. These technologies are the foundation that supports society and industry both in Japan and overseas, and we are contributing to the creation of a future society based on our long-standing technologies and innovations.

As we move toward a sustainable society and as innovations in CO2 reduction and alternative energy technologies advance, we are contributing to the creation of environmental value by supplying compressors that compress and transport CO2 to various facilities. As compressors are used over long periods of time, in recent years we have also focused on solution businesses such as compressor modifications to respond to changes in plant operations.

As water shortages worsen, demand for large pumps is increasing both in Japan and overseas. We provide large pumps for water and sewage treatment plants and power plants, and overseas we participated in the Toshka project in Egypt. This is one of the world's largest pumping stations, supplying 334 tons of water per second and contributing to the development of agriculture in the desert region. We were responsible for everything from design to installation, working on a project that has brought water to the land of Egypt.

Japan is a mountainous country, and tunnels are essential for infrastructure development. Large axial flow fans and jet fans are used for tunnel ventilation, and we also provide fans for thermal power plants and steel mills, blowers for sewage treatment plants, and ventilation fans for bullet trains and nuclear facilities. These advanced blowers are made to order, and we take care of everything from design to after-sales service.

Logistics systems support product management and cargo handling operations in factories and distribution centers. Our main products include the Racrew compact unmanned transport vehicle, the HITLOMANS product management system, and the LIMSORTER cargo handling support system. We also offer total system proposals that include equipment from other manufacturers in the same industry, as well as a full range of services from engineering to delivery and after-sales service.

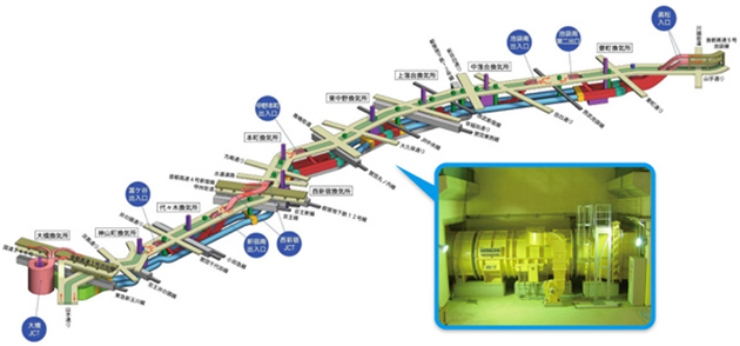

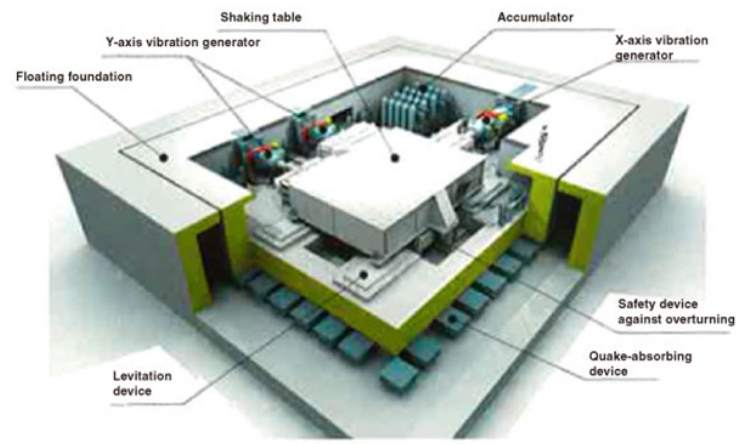

In the testing machine business, we develop and manufacture dynamic mechanical testing systems that support research and development into the behavior of Shinkansen trains during earthquakes, contributing to the safety of society. We are also developing experimental systems to reduce earthquake damage and improve the safety of Shinkansen train travel, including systems to deal with long-period seismic motion, which was a problem during the Great East Japan Earthquake.

(Photo courtesy of Central Japan Railway Company)

In manufacturing technology, innovation is required for product development. We conduct research and development in the areas of machining, joining and welding, and assembly technology, and provide high-quality, reliable products. In particular, our manufacturing technology for impellers is at the forefront of the industry. At Tsuchiura Works, we aim to become the world's most advanced machine factory through the development of manufacturing technology.

In order to respond to customer needs globally and in a timely manner, we conduct research and development in cooperation with research institutions in Japan and overseas. We aim to achieve higher performance and lower costs through technology development related to fluid performance reliability and rotor dynamics in large pumps and compressors.

FPSO (Floating Production Storage and Offloading) is a facility on a ship that produces, stores and offloads crude oil and natural gas. Compressors installed on FPSOs are required to have high discharge pressure, compactness and vibration control, and our compressors meet these requirements by using the latest technology. We are also actively involved in global FPSO projects.

The Edmonston Pumping Plant is an essential facility for transporting water from its source in Northern California to Southern California, a distance of approximately 1,100 kilometers. To cross the Tehachapi Mountains, a water conveyance tunnel with an elevation difference of about 2,000 feet (600 m) is used, and 14 of the world's largest pumps are in operation, moving about 120 m3 of water per second. The power of each pump is approximately 80,000 horsepower, equivalent to a jumbo jet. The introduction of the latest high-efficiency pumps has achieved energy savings, stable water supply and improved reliability.

The Yamanote Tunnel on the Shuto Expressway Central Circular Route Shinjuku Line is an underground tunnel 30 meters below the surface of Yamanote Street in Tokyo, with a total length of approximately 11 kilometers. The opening of this tunnel has helped to disperse traffic and facilitate access to the city center. We installed ventilation equipment and an automatic control system for nine ventilation stations in the tunnel, which supply fresh air to the tunnel. By exhausting the fumes from passing vehicles through an exhaust tower 40 meters above the ground, we have created a safe and comfortable environment inside the tunnel.

Reproduces seismic motion both dynamically and statically. Enables accurate evaluation of the seismic resistance of structures and buildings during the design phase. With a long stroke of }1m in the longitudinal direction, it reproduces long-period seismic motion and contributes to research and development of derailment prevention measures by clarifying the seismic behavior of tracks, bogies and vehicles.

With the goal of "no searching" and "no walking," we have created a new form of order picking. By allowing Racrew to move freely in all directions and automatically transport racks, we can reduce the labor required for picking operations.

Amid the international trend toward decarbonization, Hitachi Industrial Products is providing products and services that reduce environmental impact, with the aim of realizing a carbon-neutral society. For example, we are contributing to the reduction of CO2 emissions from resource extraction markets and power plants by reducing CO2 emissions through electric drive systems for dump trucks and by providing CO2 compressors using CCS* technology. In this way, we aim to improve environmental performance and realize a sustainable society.

*Carbon dioxide capture and storage

Hitachi dispatches engineers to countries around the world, engaging in both short-term and long-term initiatives. Short-term activities include order consultations and participation in international conferences. Long-term efforts encompass equipment installation, preventive maintenance, and providing overseas business training and study opportunities for young engineers. Through these efforts, we promote global technological exchange and aim to become a world-class technological organization.

Application acceptance and selection methods are explained on the gMynavi 2026h website and on the gRecruitment Informationh page of our company's website.

yRecruitment PositionszSystem Engineer (IT Engineer / Business Engineer)

After screening of documents based on the entry sheet and aptitude test, successful candidates will be interviewed (two interviews are scheduled).