In 2001, Hitachi's Measuring Instruments Group and Semiconductor Manufacturing Equipment Group merged with Nissei Sangyo to create an integrated system from development to manufacturing, sales and service. We aim to become a global leader in four business areas: nanotechnology, healthcare, core technology and value chain, and we are working to maximize our corporate value. We provide an environment in which engineers from diverse engineering backgrounds, including mechanical, electrical, information, physical, chemical and biological, can thrive.

Research and development and design development are centered on electron beam and ion beam application products, semiconductor measurement and inspection systems, life science products, bio-related equipment, and plasma etching equipment for semiconductor manufacturing. There are four systems for design positions: mechanical, electrical and circuit, information and software, and analysis.

Quality assurance is ultimately responsible for the products and systems delivered to customers. In order to ensure the functionality, quality and reliability of our products, we work with design and manufacturing to certify prototypes and conduct product shipment testing.

We design, operate, maintain and create various systems to improve the efficiency of our own factory production lines. We develop product and cross-divisional technologies and perform facility management to support manufacturing on the production floor.

We provide user support, training and demonstrations of our products to customers. We are also responsible for developing applications while taking into account the needs of our customers.

Semiconductors are an essential part of our lives. Innovations in semiconductor technology, which play an important role in the control of equipment in a wide range of fields, make our lives safer and more comfortable, while also making various systems more efficient and compact, and reducing the burden on the global environment. In addition, the role of semiconductors is becoming even more important due to the spread of IoT and AI, which connect all things to the Internet, and the use of big data and cloud computing. Our semiconductor manufacturing equipment, getching systemsh, are essential for semiconductor manufacturing processes, and contribute to our future lifestyles with cutting-edge technology.

EEtching systems

We have a unique product lineup for semiconductor metrology and inspection equipment that is at the forefront of electronic device manufacturing, meeting the needs for further miniaturization and power saving. Our main products, such as the world's top-selling CD-SEM, are the result of joint research and development with semiconductor manufacturers, and we deliver world-class solutions.

EScanning electron microscope

EWafer surface inspection equipment, etc.

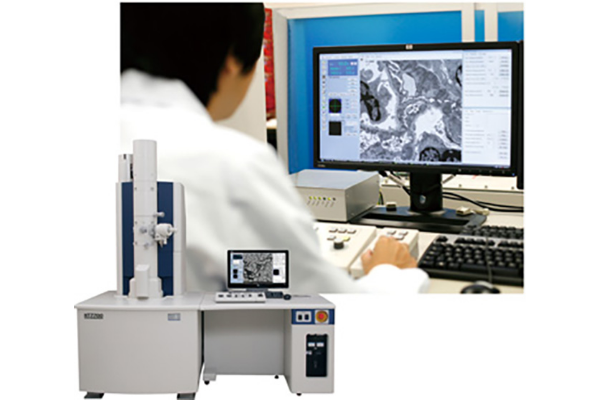

Advanced analysis equipment that is used in a wide range of fields, including the environment and industry. Our electron microscopes, such as scanning electron microscopes and transmission electron microscopes, contribute to the development of new materials and materials, as well as the development of cutting-edge science and technology, such as biotechnology research.

EElectron microscopes (SEM, TEM)

EFocused ion beam processing and observation equipment, etc.

The world's first clinical testing automatic analyzer to integrate immunological analysis functions into biochemical analysis equipment. Our automatic analyzers have contributed to the spread of clinical testing and diagnostic support through improvements in testing efficiency, measurement accuracy, and maintainability. They are now indispensable for health management and the early detection of various diseases around the world. [Gene analysis equipment] Even in this day and age of remarkable scientific progress, there are still many things about DNA that are not yet understood. Our bioanalysis technology contributes to the dramatic development of biotechnology, and is opening up new worlds such as tailor-made medicine and drug discovery.

EBiochemical auto-analyzer

ESpecimen pre-processing system

EDNA sequencer, etc.

ESpecimen testing equipment

ESmart lab solutions

Based on the accelerator element technology and plant control technology that Hitachi has cultivated to date, we are developing advanced cancer treatment technology with customers in Japan and overseas and providing it as a treatment system. In particular, we are responding to the challenges facing healthcare with innovations in products and solutions such as particle beam therapy systems, which are one of the most advanced forms of cancer treatment using radiation, and support services for medical institutions involved in PET (Positron Emission Tomography) testing. In addition, we are contributing to the development of science and technology from the perspective of manufacturing by designing and manufacturing superconducting experimental devices and superconducting magnets for various projects across countries, and also applying our technology to consumer products such as medical devices.

EParticle beam therapy systems

EPET support services

ESuperconducting applied devices

As a job category that crosses all product fields, we are involved in reforming the development and design process through digital engineering, developing embedded control systems, and developing prototypes for new businesses and products, as well as production equipment. We are building a stable corporate foundation from design to manufacturing by linking the development of processing and automation technologies, production line design, and other activities. In the Technology Development Division, we are strengthening our core technologies and promoting the development of leading-edge technologies, and we are considering technology strategies for future business creation.

We identify fundamental customer issues and promote the development and commercialization of solutions. We are strengthening existing businesses and creating new businesses by utilizing data analysis, AI, and other technologies in Hitachi High-Tech's gsee, measure, analyzeh technologies. You will also be involved in system development and operation to realize digital solutions.

This is an important job that protects the company's intellectual property. Our company utilizes electron beam technology, optical technology, etc., and is approaching various industries, including semiconductors and medical applications. The Intellectual Property Division also covers these areas, so it is possible to acquire a wide range of knowledge.

As for the content of the work, you will be involved in the following work.

In addition to providing intellectual property analysis information that contributes to business strategy planning, intellectual property information is disclosed as a communication tool.

We propose IP strategies to business divisions, create and register IP based on agreed IP strategies, and carry out IP clearance for other companies' IP.

As a quality assurance professional, you will check that finished products meet the required quality standards, and carry out systematic activities to ensure that customers are satisfied and reassured even after delivery.

Specifically, you will be involved in the following tasks.

EPlanning and conducting product shipment inspections

EVerifying and conducting certification tests for newly developed products

EConducting certification tests for newly adopted parts, and monitoring and providing guidance to suppliers

EProviding technical support and investigating malfunctions in field equipment. Providing instructions and advice to engineers, and providing support for recovery through business trips.

Hitachi High-Tech's core technologies are used in a wide range of fields, including electron beam technology, ultrafine processing technology, high-density energy processing technology, image processing technology, sensing technology, and mass analysis technology, which are used in electron microscopes and evaluation equipment. These technologies support product development at the forefront of fields such as semiconductor processing and medical care, and plasma control technology in particular plays an important role in next-generation LSI processing. Hitachi High-Tech's technologies in these fields are recognized as world-class.

Hitachi High-Tech's CG6300 measuring SEM achieves the highest resolution, measurement accuracy and repeatability, and has improved basic performance and productivity. It also achieves high-precision process monitoring and offline recipe support, and continues to meet the challenge of next-generation technology. This product, which has the world's leading market share, symbolizes our innovative technological capabilities that earn the trust of our customers.

First developed in the late 1970s, the wafer surface inspection system using laser light scattering has continued to improve in sensitivity and has become a long-selling system indispensable to semiconductor manufacturing. The current model of the LS9000 series, the LS9300A, which was developed in 2005, is equipped with high-speed dynamic control technology and a high-sensitivity sensor, and achieves high-sensitivity, high-speed inspection. It is also equipped with a non-contact wafer backside transfer system, which greatly contributes to quality improvement.

This is a dry etching system that uses ions and reaction gases in plasma to perform microfabrication of semiconductor devices. Devices in the 20nm generation and beyond require advanced and complex processes such as double patterning, 3D structures, and support for new materials. The system is equipped with a unified interface and a high-precision modularized chamber, providing expandability and flexibility to support next-generation devices.

The HT7800 series is a 120kV transmission electron microscope (TEM) that can be used in a wide range of fields, including biomedical and nanotechnology. It is equipped with three types of lenses that enable both wide-field, high-contrast observation and high resolution, and achieves the highest resolution in its class. In addition, the new design makes it easy to use for routine work.

This equipment analyzes the components of blood and other substances to assess the health of organs such as kidneys and liver, and to test for various diseases. It is widely used in a variety of settings, from small medical facilities such as clinics to large-scale clinical testing centers that process tens of thousands of samples per day.

This system contributes to the efficiency of testing operations by pre-processing (centrifuging, dispensing, applying bar codes, opening and closing lids, etc.) and automatically transporting blood samples used in analyzers.

We provide systems that analyze the base sequence and length of DNA, the blueprint of life. They are used in a wide range of fields, including medicine and health, and for DNA identification in criminal investigations.

We offer DX solutions designed to improve the efficiency and accuracy of testing operations by integrating them with analyzers and transport equipment.

Hitachi's spot scanning irradiation technology delivers particle beams with high precision to tumors with complex shapes, minimizing the impact on normal tissue. In addition, when combined with dynamic tracking irradiation technology, it provides high-precision treatment even for tumors that move.

When medical institutions introduce PET scans, we offer a "PET Support Service" that provides comprehensive support from the design to the operation of accelerators and radiation facilities. We provide comprehensive support for everything from equipment procurement and maintenance to drug production.

We develop superconducting magnets and magnetic field generators using high-temperature superconducting technology. In particular, we are focusing on the development of superconducting magnets that do not require coolants and reduce power consumption.

With the vision of gsimplifying high-tech processesh, we have bases in 25 countries and regions overseas, and more than 70% of our sales are generated overseas. This allows us to be in touch with the world's most advanced technologies, quickly grasp market needs, and contribute to global value creation.

In April 2024, Hitachi's healthcare business was transferred to Hitachi High-Tech, and the Healthcare Business Headquarters was established. Through this integration, we will promote the gdiagnosis x treatment x digitalh strategy, accelerate healthcare innovation to realize cancer treatment and personalized medicine, and aim to improve QoL and create a society where people do not have to fear cancer.

We have acquired a new factory site in Hitachinaka City, Ibaraki Prefecture, and will strengthen the development and manufacturing of molecular diagnostic equipment. By promoting automation and efficiency, we will provide high-quality products quickly, and contribute to the improvement of the quality of testing and people's QoL.

A new production building will be constructed in the Kasado district of Yamaguchi Prefecture with the aim of increasing production capacity for semiconductor manufacturing equipment, and production will begin in fiscal 2025. The new production building will double production capacity through digitization and automation, and will respond to increasing demand. In addition, it will contribute to the realization of a decarbonized society with the goal of achieving carbon neutrality.

The application acceptance and selection methods are explained on the "Mynavi 2026" website and on the "Recruitment Information" page of our company's website.

yRecruitment Positionsz Please select one of the following positions and apply.

Engineering positions (research, design and development, quality assurance, production engineering, sales engineering)

Sales and business staff (sales, accounting, information systems, human resources, etc.)

After reviewing the documents and aptitude tests based on the application form, successful candidates will be interviewed (several times).