- TOP

- Job Matching Navigator

- Hitachi Social Infrastructure Control System

Department for Job Matching

Hitachi, Ltd.

In today's rapidly changing social climate, social infrastructure systems are required not only to operate stably, efficiently, and conveniently, but also to be able to quickly capture and analyze changes in the world and respond flexibly. We at Social Infrastructure Control Systems globally provide mission-critical ginformation and control systemsh that support social infrastructures such as electric power, energy, transportation, water environment, and industry, which are indispensable to our daily lives.

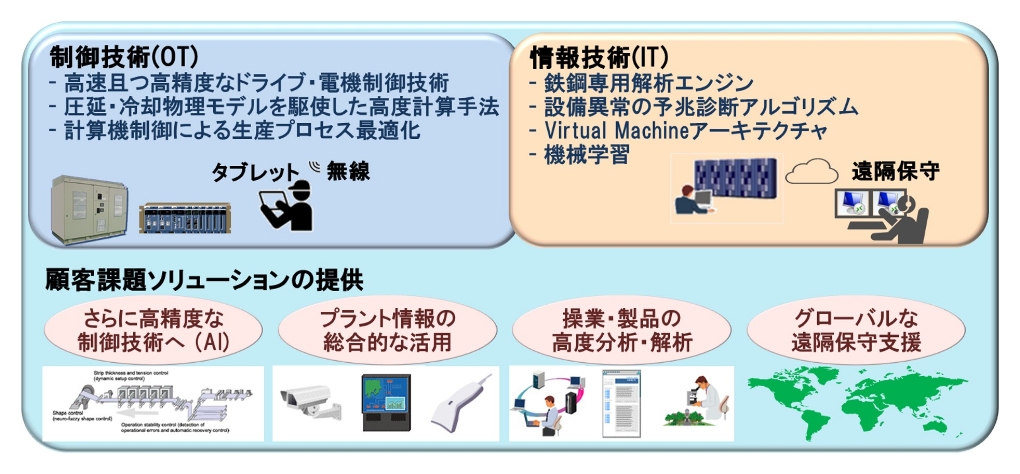

By connecting information technology (IT) and control/operation technology (OT) with software and digital technology, we promote DX of information and control systems to realize social infrastructures that can quickly adapt to social and business challenges.

We provide new value to the world by reflecting Hitachi's technological capabilities in our products in response to domestic and international market trends, social needs, and customer requests.

We investigate and analyze customer needs, consider optimal software and hardware, and work with customers to resolve issues through system design.

We realize DXing of processes from design to production, as well as expansion of production volume and improvement of production efficiency from both technical and IT system perspectives.

We contribute to ensuring Hitachi quality by checking from the upstream process whether products and systems meet the prescribed functions, performance, durability, etc., and preventing problems before they occur.

The electric power and energy industry is undergoing rapid changes, including environmental issues, institutional reforms, the introduction of market principles, and the emergence of natural disaster risks.

In this uncertain environment, we are contributing to the realization of a safe, secure, and comfortable carbon-neutral society by building environmentally friendly and sustainable energy infrastructure through collaboration with various stakeholders by integrating world-class IT (information technology) and OT (control technology).

We aim to be a leading manufacturer of social infrastructure GX/DX in the green energy field.

Our power generation, transformation, and storage control technologies are at the core of a stable power supply to meet the ever-changing power demands of the times. With our extensive experience and knowledge of products installed in power plants and substations and their operators, we are able to propose and provide optimal monitoring, control, and protection systems to solve social issues such as system upgrading and carbon neutrality. We also develop cyber and physical security products to realize stable and safe operation of facilities and DX business using data analytics based on captured digital data.

Hitachi provides a wide range of total solutions as Japan's No. 1 vendor of railroad solutions. In the railroad systems field, we develop and provide Shinkansen and conventional train operation management systems, onboard information display systems, and power management systems to support safe and efficient railroad operations in Japan and overseas. We also contribute to the construction of next-generation railroad systems that improve transportation stability and comfort by utilizing IoT and AI technologies to monitor operational status in real time and improve maintenance efficiency. We will continue to support the future of transportation infrastructure with reliable technologies and solutions.

In the water environment system field, we are involved in a wide range of water-related fields, centering on water supply and sewage projects. Currently, the lack of financial resources, technological succession, and aging infrastructure facilities due to the declining birthrate and aging population are becoming social issues. Hitachi is developing and proposing new products to solve these issues by combining experience gained from past deliveries with new technologies. We are also working to realize safe, secure, and sustainable water environments by providing water environment systems tailored to the characteristics and needs of each region.

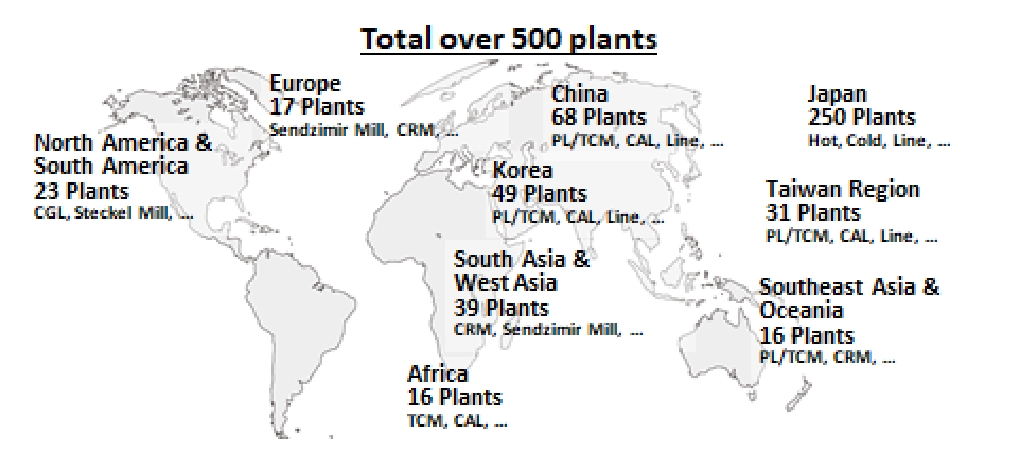

We provide various solutions that fuse the latest optimal control with IT and OT technologies, centered on steel mills that produce nonferrous metals such as iron, copper, and aluminum, which are indispensable as key materials for industry. We have a proven track record of delivering systems to global steel mills, and we routinely have opportunities to be involved in global situations in each phase of system planning, planning presentations, meetings to determine requirements and specifications, system development, and on-site demonstration testing.

We operate in three business areas: environmental information management, control system security, and information and control solutions. In environmental information management, we provide environmental information management solutions that help companies visualize, analyze, and improve their environmental management. In control system security support, we promote DX activities and ensure both stable operation and security of control systems. In information and control solutions, we design and develop components used in social infrastructure information systems and provide engineering and maintenance services, contributing to stable operation of control systems and high-quality manufacturing. In addition, we are also promoting commercialization by incorporating the latest technologies, such as AX through the use of generation AI. Through these business activities, we contribute to solving social issues.

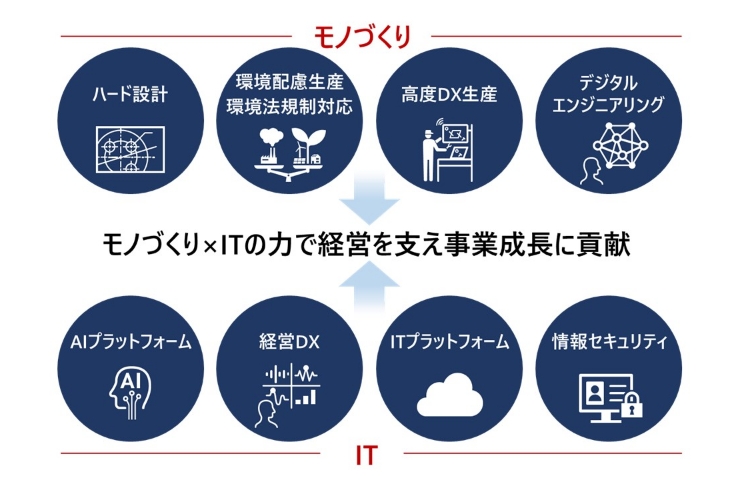

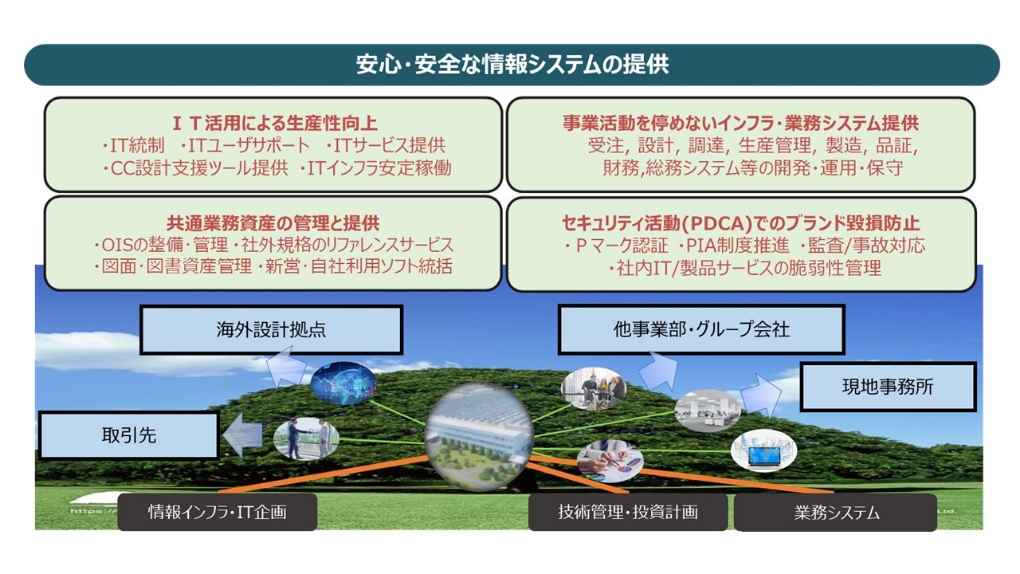

Control panels and electronic equipment that support the stable operation of social infrastructure are characterized by specifications that vary by customer and product and require extremely high quality. The Monozukuri Division is engaged in technological development and operations that integrate production management, hardware design, and production sites with the aim of reducing environmental impact while producing these products efficiently and with high quality. Meanwhile, the Information System Division is responsible for providing platforms for advanced technologies such as generative AI and DX, as well as information security measures in preparation for cyber attacks, all of which are indispensable for the evolution of manufacturing. In this way, the Monozukuri and Information System divisions work in unison to support management and contribute to business growth.

The Quality Assurance Department is the guardian of quality to maintain the gtrust of the Hitachi brandh and is involved in a wide range of activities throughout the product lifecycle, from product development to inspection, on-site adjustment, and post-delivery operation. Control system products that support social infrastructure require high quality and reliability. They consist of hardware, software, and maintenance services that are designed to be used 24 hours a day, 365 days a year. We deliver high-quality products to society through gtotal quality assuranceh as well as individual quality assurance. Our activities are not limited to the domestic market, but are expanding overseas as well.

Electricity is produced at large-scale, centralized power plants, such as nuclear and thermal power plants, and renewable energy plants, such as wind and solar power plants, and delivered to consumers in buildings, factories, and homes. This delivery of electricity is called power distribution. We provide power distribution solutions to deliver electricity safely, stably, and efficiently 24 hours a day, 365 days a year, from generation to transmission, through substations that convert voltage, and to distribution that sends electricity to urban areas. By combining our strengths in advanced OT, advanced IT, and highly reliable products, we are making a significant contribution to the next-generation energy society by developing monitoring and control systems and the latest power solutions that implement wide-area operation of electric power and advanced grid stabilization technologies, both in Japan and overseas.

In order to maintain a high-quality power supply, the balance between production and consumption of electricity (supply-demand balance) must be maintained. For this purpose, it is essential to have a central feeder control station system (central feeder system) that controls hundreds of generators to maintain the balance between supply and demand. Until now, central feeder systems have been developed for each area of general transmission and distribution companies. In the future, a platform that can be used commonly by each utility (excluding Okinawa) will be required to promote merit orders on a nationwide scale, improve resilience and reduce social costs, and be scalable, flexible, and transparent in preparation for system changes. Therefore, it was decided to share a centralized feeding system, which will be developed by Hitachi.

Power systems are divided into tiers, and we are developing a system that collects various information on power distribution facilities and performs centralized monitoring and control from a distance. For power distribution facilities at dozens of power plants and substations, we perform everything from planning to maintain appropriate voltage and tidal current values, to implementing remote control and responding in the event of an accident. In addition, in order to respond to the deregulation of electric power and the massive introduction of renewable energy, we are working on the advancement of grid stabilization technologies that contribute to the maintenance of power quality, such as frequency maintenance and voltage optimization, and are participating in various demonstration experiments in Japan and overseas.

There is a limit to the capacity of power transmission facilities to transport electricity from power plants to consumers, and the massive introduction of renewable energy will create further shortages. Since it is costly and time-consuming to expand transmission facilities, a system to effectively utilize the available capacity of existing transmission facilities (Connect & Manage) has been introduced mainly in Europe. Hitachi is developing a Japanese version of Connect & Manage, a non-firm connection system that manages grid congestion and connects during times when the grid is free.

In addition to power distribution automation systems that perform power outage restoration and voltage stabilization control of power distribution systems, we are working to establish a solution business that captures the entire power distribution operations.

With the deregulation of electric power, there is a need to curb capital investment and improve work efficiency, while at the same time, the operation of power supply operations is becoming more complex due to the introduction of large amounts of renewable energy sources with fluctuating output. In response to this, we are developing new solutions that utilize technologies such as IoT/AI/Big Data analysis, such as voltage analysis systems for power distribution systems and system (facility) planning support systems that contribute to more efficient power distribution.

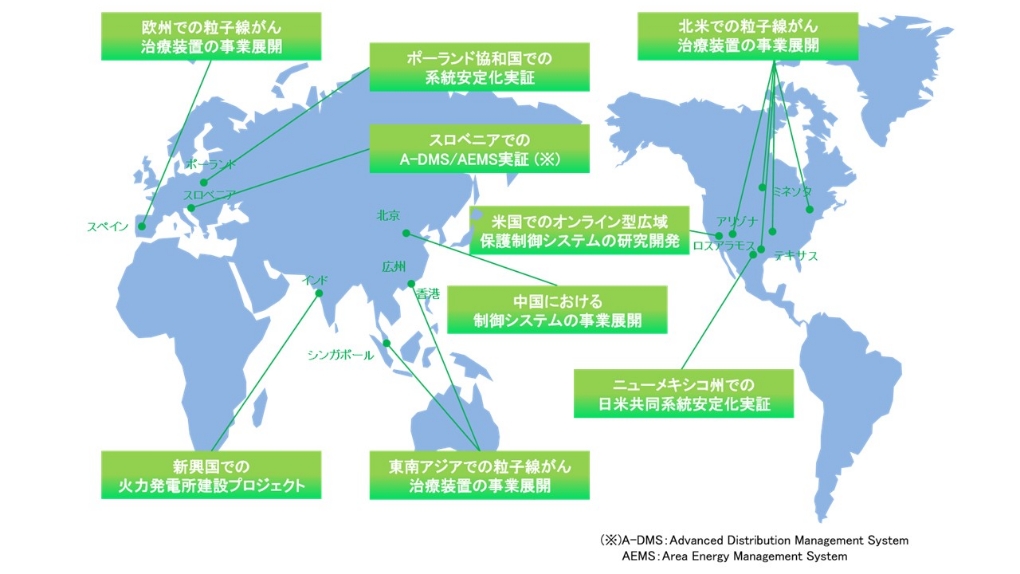

The development needs for electric power infrastructure are increasing in line with the economic development of emerging countries. At the same time, the growing momentum to curb global warming in recent years has accelerated efforts to reduce environmental impact and promote clean energy around the world. Under these global circumstances, Hitachi's Power Control Systems Division has been participating in and achieving results in power system stabilization projects and smart community projects that can withstand the massive introduction of renewable energy in order to realize efficient power energy operations. In collaboration with Hitachi Energy Corporation, which has joined the Hitachi Group, we will provide society with an integrated power control system business for power grids, power transmission and distribution, and power generation, and accelerate our global expansion to solve social issues related to electric power energy.

We contribute to the realization of a carbon-neutral society by reducing CO2 emissions that contribute to global warming through the promotion of thermal power generation that reduces environmental impact by introducing carbon capture and storage (CCS) technology and hydrogen/ammonia co-combustion/mono-firing technology, and nuclear power generation that does not emit CO2 during operation. In combination with pumped storage power generation that makes effective use of surplus power at night, etc., we enable efficient operation of electric power. We are making significant contributions to the next-generation energy society by developing state-of-the-art solutions in Japan and overseas, including monitoring and protection control systems that enable wide-area operation of electric power and advanced grid stabilization, DC power transmission equipment that applies power electronics, and storage battery systems for the grid.

Electricity cannot be stored, and in order to maintain a high-quality power supply, the balance between production and consumption of electricity (supply-demand balance) must be constantly maintained. In order to respond to the deregulation of electric power and the mass introduction of renewable energy, we are also actively working on the advancement of grid stabilization technologies that contribute to maintaining electric power quality, such as frequency maintenance and voltage optimization, and are participating in various demonstration experiments in Japan and overseas.

We provide protection and control systems for the power grid, which is a social infrastructure, by detecting lightning accidents at high speed and disconnecting from the power grid so that the grid can be operated only with a healthy power grid. In recent years, we have also been designing and developing protection and control systems for the introduction of digital substations using advanced sensing and network technologies. We also contribute to the stable operation of power grids by applying power electronics technology to direct current interconnection facilities (HVDC).

We provide protection and control systems and substation equipment for substations that supply electric power to electric railroads, one of the most important public transportation infrastructures. This system provides a stable power supply using sequence control technology based on real-time information from substations, and supports the stable operation of rolling stock in coordination with upper-level power command systems, while contributing to the prevention of abnormal spillover by monitoring and controlling substation equipment and protecting equipment in the event of an error. We are also engaged in the design and development of digital technology and DC disconnect devices.

By monitoring and controlling distributed energy sources, we support both the main use of renewable energy sources and the stable supply of electricity through system integration of grid edge solutions that enable the reduction of power fluctuations caused by intermittency, such as solar power, and the adjustment of the supply-demand balance through optimal storage and discharge control of surplus power. This will contribute to the realization of a decarbonized society. In providing grid energy storage systems with a proven track record globally, we provide upstream design and project management based on requirement definition and needs. Leveraging our overseas track record, in the future we will accelerate the deployment of our grid edge solution group for micro-grid applications that can be used in small-scale environments such as remote islands.

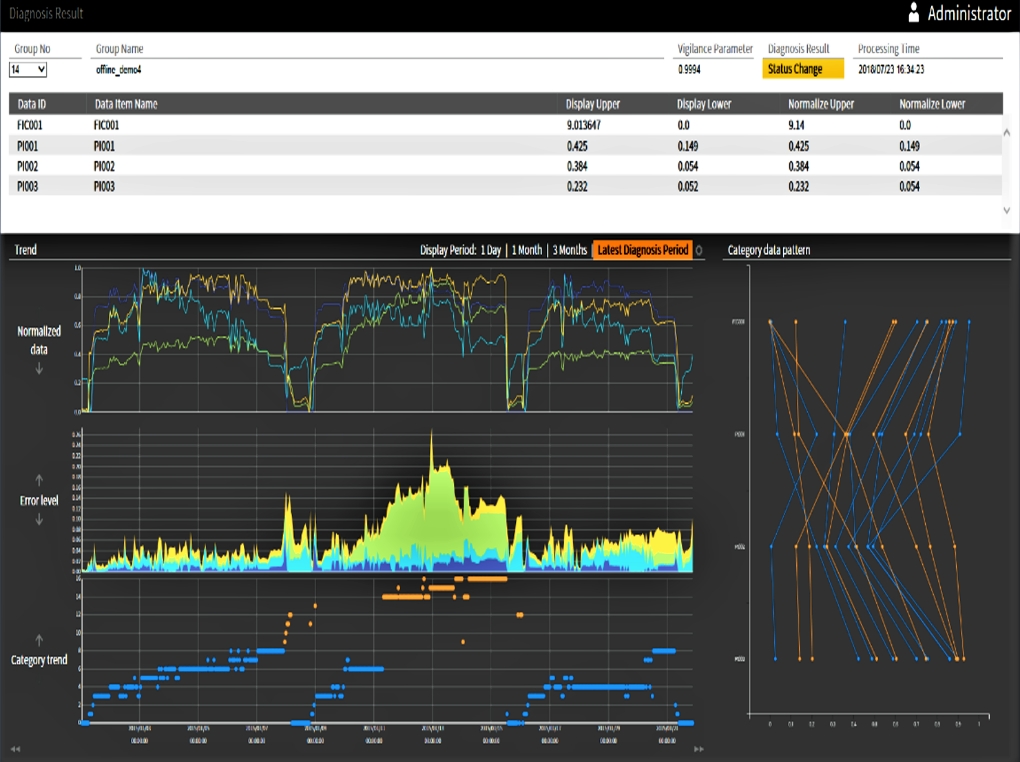

We support social infrastructure by providing coordinated control, high-speed control, coordination control, protection systems, etc. using real-time autonomous decentralized control systems for major equipment such as ultra-supercritical pressure boilers, steam turbines, gas turbines, generators, and pumped storage power generators in large-scale thermal/hydraulic power plants and nuclear reactors, turbines, and generators in nuclear power plants. We support social infrastructures. In addition to human-machine systems based on ergonomics, we also provide advanced operation monitoring through knowledge engineering-applied operation support and predictive equipment anomaly detection technology using data analytics. Furthermore, we are working on commercialization of DX solutions and development of cyber-physical security products for stable and safe operation of power plants.

We are working on particle beam (proton beam and heavy particle beam) cancer therapy systems, utilizing the technology we have cultivated in nuclear power. Particle beam cancer therapy is one of the most advanced treatment methods that minimize the effects on normal areas of the body, allowing treatment while maintaining quality of life (QOL). We have developed a control system that precisely delivers particle beams accelerated by a synchrotron accelerator according to the shape of the affected cancer site, and provide solutions that are tailored to the needs of patients and medical staff.

With the growing momentum to curb global warming in recent years, efforts to reduce environmental impact and clean energy are accelerating around the world. Under these global circumstances, we will accelerate our global development to solve social issues related to electric energy by providing integrated power control systems for power grids, power transmission and distribution, and power generation to society in cooperation with Hitachi Energy Corporation, which has joined the Hitachi Group. In power generation control systems, we are participating in projects to upgrade facilities and enhance the performance of power plants around the world, and we are also developing control solutions based on nuclear technology overseas, including the global deployment of particle beam therapy systems.

Our train operation management systems support and realize the gnaturalh expectation that trains will arrive on time. We continue to support world-class railroad systems through the development and improvement of train operation management systems that cover not only all of Japan's Shinkansen lines, but also Taiwan High Speed Rail and the majority of conventional lines in Japan, including those in the Tokyo metropolitan area, Chukyo district, and Keihanshin district. To ensure safe, comfortable, and convenient train operations, we provide advanced and highly reliable systems that operate 24 hours a day, 365 days a year, automatically controlling railroad signaling equipment and train spacing, and distributing real-time train information to passenger information displays and voice guidance systems installed at stations.

Make the train into an information station! We provide an onboard information service using video images so that a variety of users can use trains with peace of mind. The universal design of the system, which takes into consideration the elderly and colorblind people, provides users with easy-to-understand information displays. In addition, we provide digital signage that supports a variety of video advertisements, such as multiple screens that can be linked or independent of each other. In the Tokyo metropolitan area, digital signage is used daily on the Yamanote Line and other lines, and is being expanded sequentially to the Kansai and Kyushu areas.

Railroad power management systems are indispensable to ensure a stable supply of power necessary for the stable operation of trains. To ensure a reliable supply of power not only to trains, but also to signals and station facilities, the system monitors and controls the power facilities of railroad companies 24 hours a day, 365 days a year, controlling off-peak power transmission according to train operation status and maintenance plans, supporting and automatically restoring power after power outages and other abnormalities, and measuring and forecasting power consumption. We are also engaged in research and development of next-generation systems to achieve carbon neutrality by combining the expertise of our engineers who are well versed in railroad and electric power operations. We aim to realize a sustainable railroad system by analyzing power usage and optimizing energy through integrated control of timetables, trains, storage battery recharge/discharge, and other systems.

The greatest feature of Japan's railroads, gon-time operation,h cannot be described without train operation management systems. Hitachi, which possesses many railroad technologies, has begun to develop its business overseas, including in Australia and Taiwan. In the high-speed rail market, Hitachi is aiming to export the gShinkansenh with its rolling stock, signaling systems, and train operation management systems. In the field of conventional railways, Hitachi is working to further expand its market share by using the business channels it has established in the rolling stock business. In addition, the Japanese government is supporting the development of railroad systems in emerging countries through ODA in order to support their economic development. Hitachi is cooperating through its superior railroad technology, and the train operation management systems we provide are indispensable for advanced railroad operations. We will continue to develop train operation management systems that meet the needs of each region.

Hitachi's involvement in the water business has a history of over 100 years, and we have contributed to a wide range of fields, including water source conservation, water supply and sewage, rainwater drainage, and water recycling. Since our founding, we have upheld the corporate philosophy of gcontributing to society through the development of superior, original technology and products,h and we develop and deliver products and systems that emphasize reliability, stability, and safety in order to support lifelines. To date, we have delivered electrical equipment and monitoring and control systems to more than 2,100 water treatment plants and sewage treatment facilities nationwide. In addition to our extensive track record and experience gained through many years of cooperation with our customers, we are also proposing efficient and effective systems and services that combine IT, OT and products, making the most of our own cutting-edge technologies.

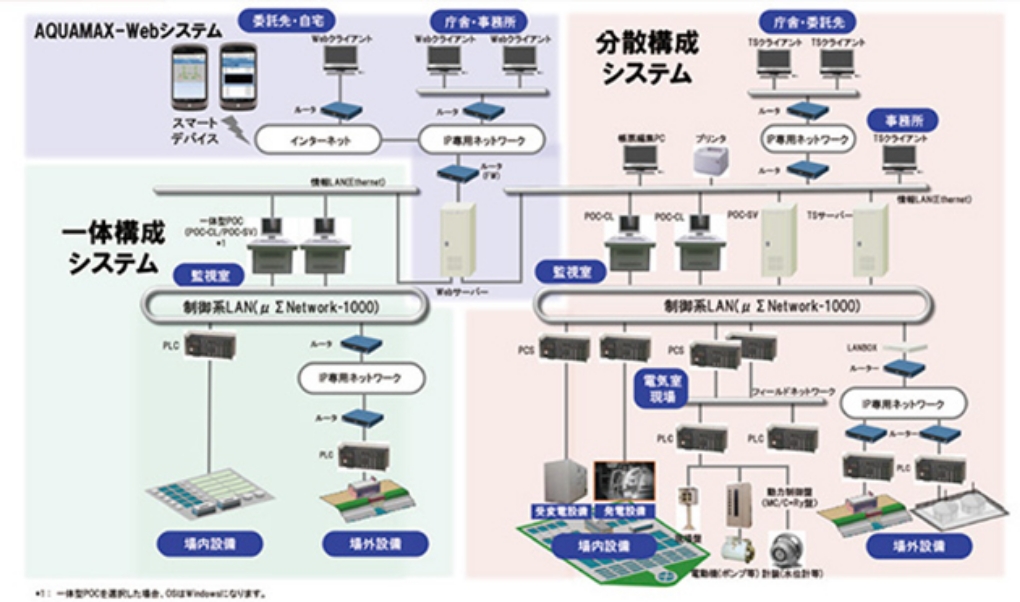

Hitachi proposes, designs, and manufactures systems tailored to customer needs, and is involved in the entire process from shipment to on-site trial operation. AQUAMAX is the core monitoring and control system that monitors and controls water and sewage facilities.

The basic concepts are a scalable architecture, seamless integration (on-site/off-site, information system integration), and an HMI that supports business operations. It is a highly reliable and flexible system that can be expanded in stages and partially updated. While enhancing security, it allows monitoring information to be shared anytime, anywhere via the Internet or smart devices. AQUAMAX contributes to strengthening the operating base of water and sewage works and creating a safe and secure water environment.

In water supply operations, it is important to be able to respond to fluctuating water demand over time and to supply water stably without excess or shortage. Hitachi's water operation planning technology uses forecast data such as temperature and weather conditions, as well as the day of the week, to predict water demand for the day, and then formulates an operation plan that satisfies the predicted water demand while also ensuring that water supply facilities such as water reservoirs, intake pumps, and water supply pumps operate stably. In addition to ensuring a stable supply, we also contribute to the water business by drawing up plans that take energy conservation into account, such as prioritizing the use of pumps with high power efficiency.

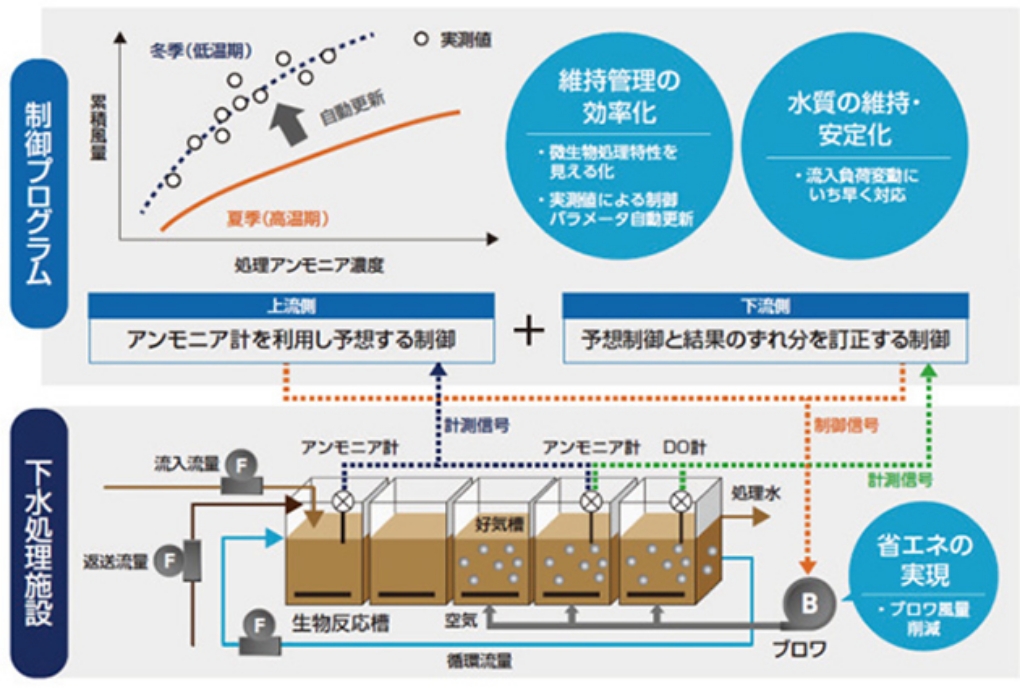

This is a technology that uses ICT to efficiently control the nitrification process in sewage treatment facilities. The nitrification process is a process that changes the ammonia nitrogen in sewage into nitrite nitrogen and nitrate nitrogen, and it is optimized by learning from past data. Specifically, the degree of nitrification is controlled by measuring the concentration of ammonia nitrogen in the sewage in real time using an ammonia meter, thereby stabilizing the treatment process and maintaining water quality. Furthermore, by utilizing a treatment characteristic model based on past data and predicting the required air volume, excessive air supply is suppressed, thereby achieving energy savings. This technology enables sewage treatment that reduces operating costs while reducing environmental impact.

By utilizing plant data from water treatment plants and sewage treatment plants, we can improve the operation and management of water and sewage facilities, and realize a safe, secure, and sustainable water cycle. By analyzing collected data using statistical processing, simulation, and AI, we can understand the operating status of facilities and fluctuations in water volume and quality, and provide appropriate operation and management methods and automatically adjust facility operating parameters. Through these measures, we can reduce the workload of operation managers, address the problem of a shortage of skilled workers, and contribute to the realization of a decarbonized society through energy conservation and reduced environmental impact.

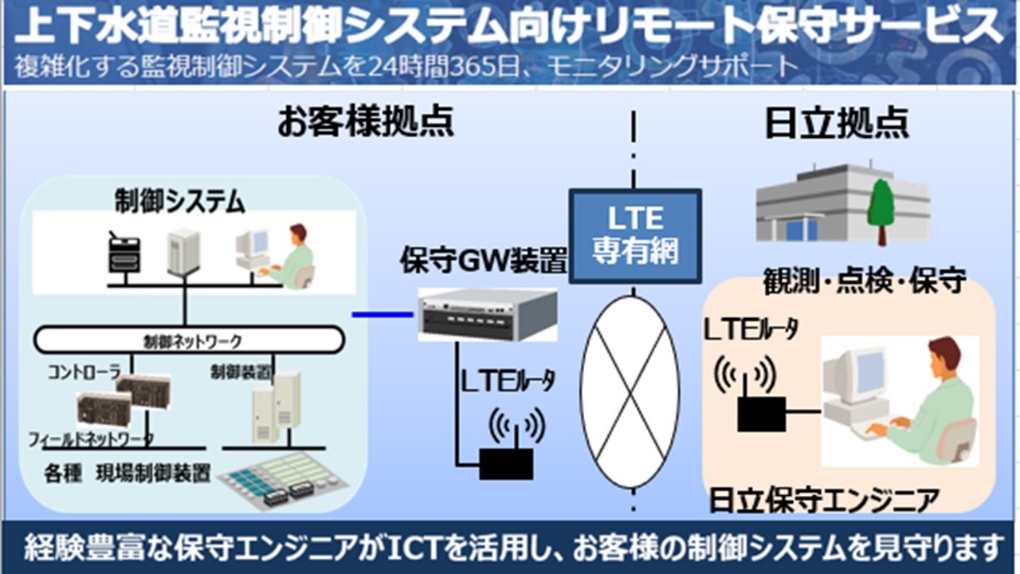

The gremote maintenance service for water supply and sewage monitoring and control systemsh provides 24/7 monitoring support, constantly monitoring increasingly complex monitoring and control systems and analyzing fault information. This enables rapid response to faults and supports stable system operation. In addition, regular inspections and diagnoses are carried out in a remote environment, and in the event of a fault, we support rapid recovery work. Furthermore, we aim to detect and block unauthorized access and to detect security incidents at an early stage, thereby reducing security risks. Remote maintenance reduces the frequency of dispatching maintenance staff to the site, and also achieves cost reductions. This enables efficient and safe operation of water environment systems.

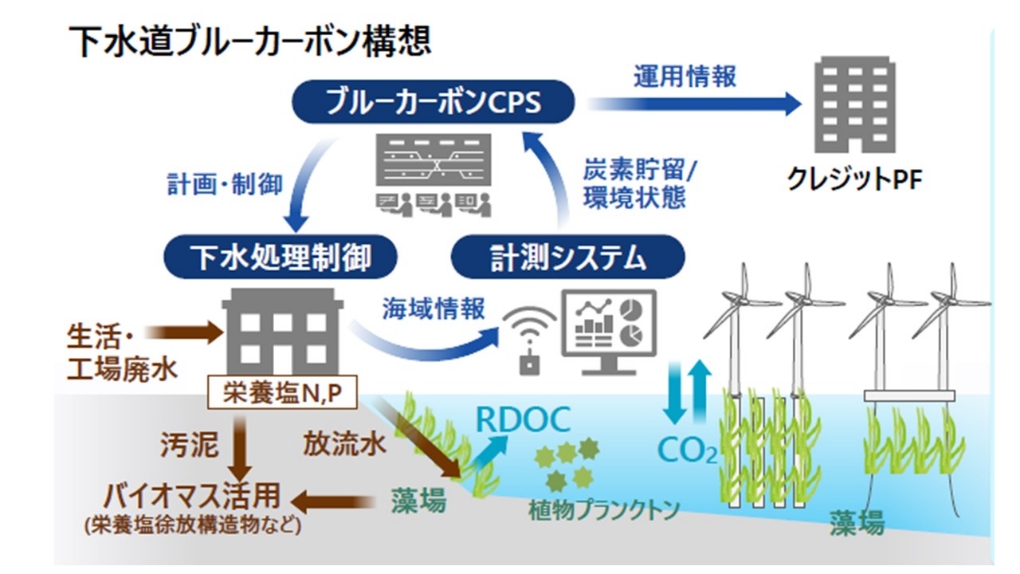

The Blue Carbon Initiative for Sewage Systems is an initiative that uses sewage systems to promote the absorption and storage of CO2 by marine ecosystems. This initiative involves supplying the necessary nutrients from sewage treatment plants to the sea in an appropriate manner, and cultivating seaweed beds such as seaweed and seaweed. The aim is to increase the amount of gblue carbonh absorbed by the marine ecosystem and stored for long periods of time. Specifically, we will use sewage treatment control technology to manage the supply of nutrients and maintain and expand the marine ecosystem. This initiative aims to contribute to the realization of a sustainable society and decarbonization, and is being promoted in collaboration with stakeholders from various fields.

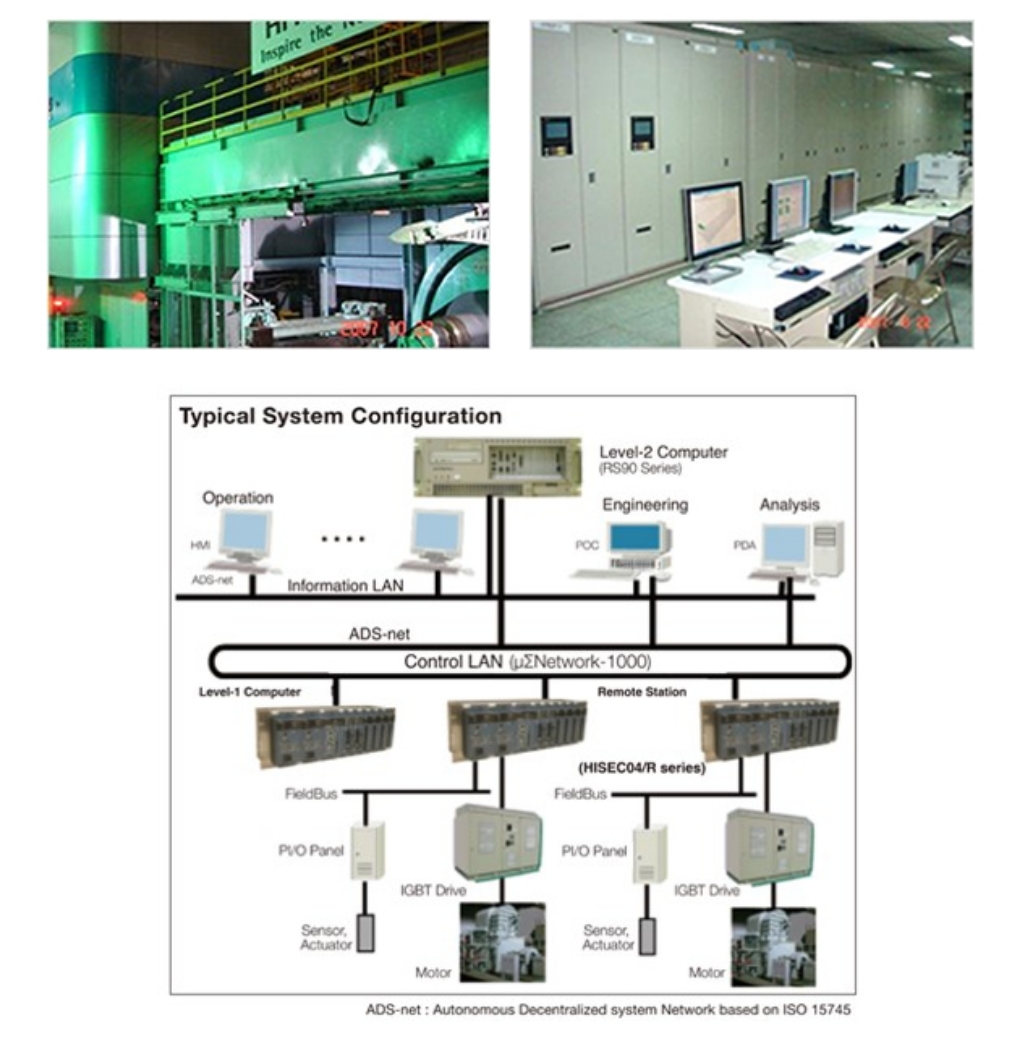

We contribute to global industrial development by developing optimal iron and steel plant control systems that combine advanced information and control systems and utilize environmentally friendly energy-saving technologies. Hitachi provides control systems and electrical equipment to iron and steel plants that produce iron, copper, aluminum and other non-ferrous metals that are essential as key materials for industry. Iron is constantly being sought for new material properties and quality, and numerous manufacturing processes are required before iron ore raw materials become final products. We meet the needs of customers who are always seeking the latest quality by developing and integrating the optimal information, control and drive technologies for each manufacturing process. We contribute to the production of high-quality steel products by building systems that synchronously control 300 to 400 motors with a single device, using variable-speed AC motor drive systems that make full use of power electronics technology, high-speed, high-capacity system control devices, network devices and the latest control technology.

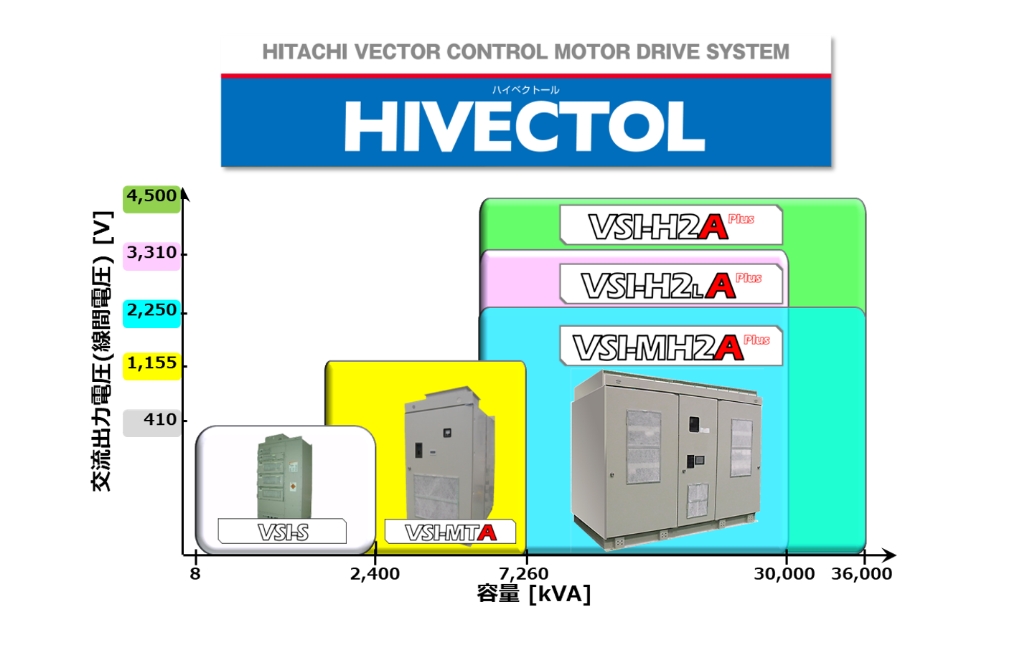

In steelmaking systems, motor drive systems (inverter drive systems) that apply power electronics are used to drive rolling mills. In developing motor drive systems, it is necessary to make full use of a variety of technical capabilities, including not only power electronics technology but also control engineering, electromagnetics, heat transfer engineering, mechanics, mechanical engineering, and other technologies, as well as data statistics and analysis technology for edge devices DX and network construction technology.

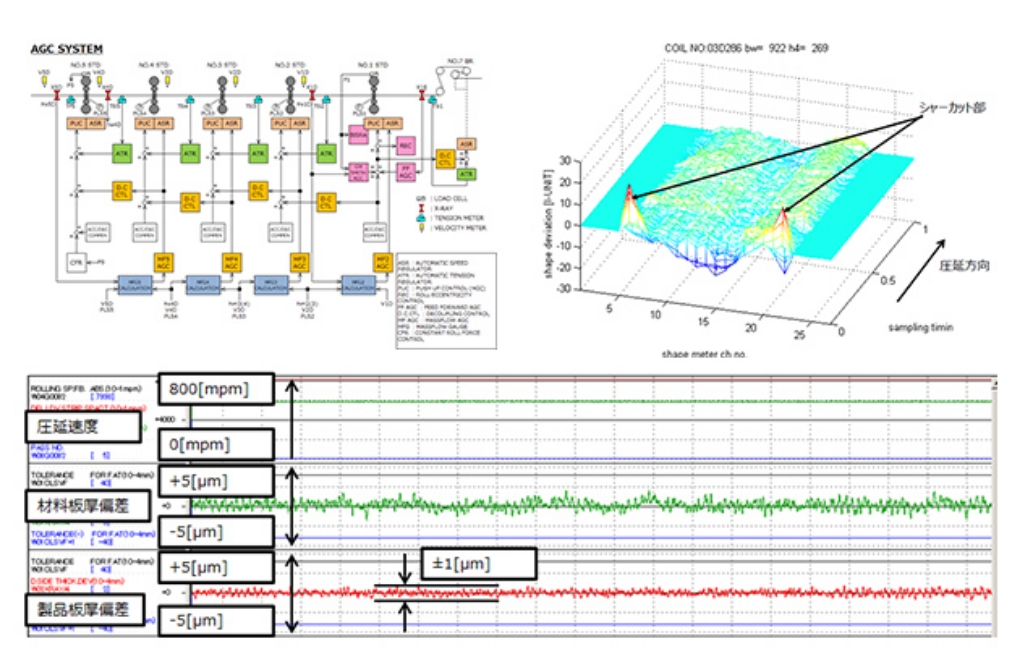

We provide control systems incorporating the latest control technologies for the steel plate manufacturing process, which is an important part of the steel plant. For hot rolling control, we have a metallurgical mechanical property prediction system that optimizes the changes in steel plate characteristics due to rolling and cooling, which affect the quality of the steel plate. For cold rolling control, we have various automatic control technologies that correct the thickness and shape of the steel plate with high precision. In addition, we have developed and provide our customers with a number of control technologies for process line control that adds value to steel sheets, such as high-precision tension control and coating weight control in annealing furnaces. Furthermore, we also propose information systems that utilize our vast rolling experience as big data to achieve a number of operational improvements. We have achieved solutions that match our customers' needs by combining this information and control, and by independently developing high-performance, high-precision motor drive systems and integrating them into a single system.

In rolling mills, the quality requirements for steel plates being manufactured, such as thickness and shape (flatness), are becoming increasingly demanding, and in particular, thickness accuracy is required to a high degree of precision of }1Êm. In addition to conventional quality control, we are designing and developing control systems that apply non-interference control, neural networks, deep learning, and other technologies. As steel plate is developed every day to help create a sustainable society, the difficulty of rolling it increases, which can lead to problems for customers, such as a decline in product quality.

We are working every day to develop technologies that overcome these problems, and we are contributing to society by providing control systems that are of high value to our customers.

In 1982, Hitachi released the world's first fully digital AC variable speed motor drive system, contributing early to the digitalization of steel plants. Our lineup can drive motors ranging from 10,000kW class main motors to auxiliary motors under 10kW. With vector control at its core, we achieve the performance requirements for rolling mill motor drive systems through various control methods including state feedback control (shaft torsional vibration suppression control), feedforward control (speed synchronization control), and load torque estimation control (impact drop compensation control). In recent years, we have been focusing on implementing DX solutions specifically designed for motor drive systems.

Steel and industrial plants are continuing to evolve in order to develop high-value-added products and optimize production processes that meet the needs of the times and society. Hitachi is developing an intelligent operation support system that automatically analyzes and proposes improvements in the event of operational problems, making full use of the vast amounts of data that are sensed in real time on the millisecond order, as well as cutting-edge control methods that feed back optimal quality conditions to control through machine learning. We are also working to create new digital solutions for the steel and industrial sectors, connecting customers from around the world via a network, and providing services that support the remote startup of new plants, as well as day-to-day stable operation and quality improvement, using both video and data.

We provide world-class, high-performance, resource- and energy-saving steel plant control systems and drive systems to customers around the world. We have a long track record of delivering systems to global steel manufacturers, and currently around 50% of our sales are from overseas projects. You will have the opportunity to work on global projects on a daily basis, in each phase of the project, from system planning and planning presentations to requirement specification determination meetings, system development and on-site verification testing. In the first few years of employment, you will be expected to play a key role in bringing a project to a successful conclusion, developing a system to realize the specifications decided with the client, and finally, conducting a performance verification test of the developed system on-site with the client.

We design and develop components (hardware and basic software) and solution systems that are used as the core of social infrastructure such as power and railway systems. Social infrastructure systems require high reliability and toughness that can operate 24 hours a day, 365 days a year, and Hitachi has achieved high-quality, high-efficiency manufacturing by building a production reform system using digital data that utilizes 3D design information in its factories, as well as CAD/CAM-based design, manufacturing and quality assurance. We make full use of cutting-edge technology to handle everything from components to engineering, including fault-tolerant (*) systems and wireless application systems.

(*) Fault-tolerant: A system that does not stop functioning even if part of the system malfunctions

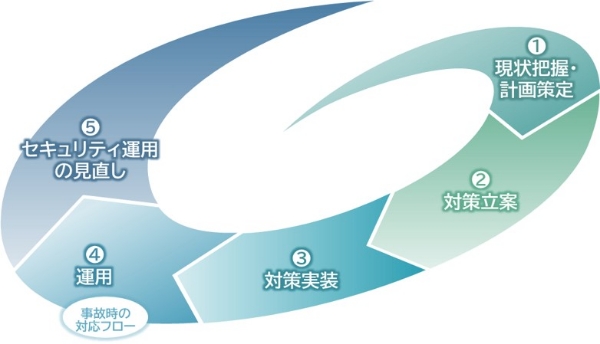

We provide support for the security of control systems throughout their entire lifecycle, in addition to ensuring the stable operation of control systems, to support DX activities aimed at business transformation. We provide the following solutions for control systems, including critical infrastructure

Companies are expected to take a proactive approach to solving environmental issues, such as responding to the SDGs and ESG investment, and are required to fulfill their social responsibilities towards the environment. Hitachi provides environmental information management solutions that gvisualizeh product and production activities from an environmental perspective, making it easy for customers to analyze, take measures, and disclose information.

We are developing control servers that can operate continuously 24 hours a day, 365 days a year, and that are required to be real-time, as platforms that support social infrastructure such as power and railways. In addition to hardware development such as CPU boards, LAN boards, and chassis, we are developing OSs for control servers that improve reliability, availability, and maintainability based on the open-source Linux, as well as network middleware that supports autonomous distributed systems.

In order to realize the intelligence of the workplace and DX, it is necessary to ensure the long-term stable operation of electronic and information equipment that is resistant to the environment and requires little maintenance. Embedded computers are fanless and HDD-less, which reduces maintenance requirements, and they are also resistant to earthquakes and dust, and are widely used in edge computing, network monitoring, physical security, and in-vehicle information display systems that utilize data collected from the workplace.

We have developed the Ê°NETWORK-1000 and other control networks that ensure openness and high reliability by using the international standard Ethernet (*) as a base and incorporating our own highly reliable technology. This allows control system communications, which require high reliability and real-time performance, and information system communications using general-purpose TCP/IP to coexist.

(*) Ethernet is a registered trademark of FUJIFILM Business Innovation Corporation.

We are engaged in highly reliable wireless engineering (consulting, SI, operational support) businesses that make use of wireless technology for mission-critical applications. The use of wireless technology for mission-critical applications is on the rise, and we are creating new businesses that meet customer needs and developing highly reliable wireless products (hardware and software).

We develop highly reliable programmable controllers that achieve optimal control (feedback control, sequence control) for mission-critical systems such as power plants and water supply and sewage systems that support infrastructure, as well as a wide variety of input/output devices that connect to field devices, to support systems that never stop, 24 hours a day, 365 days a year.

Plant operation monitoring and control requires the ability to easily grasp the operating status of the entire plant, stable operation that never stops 24 hours a day, 365 days a year, and the ability to easily respond to production conditions such as expansion, additions, and maintenance. We develop and design plant integrated monitoring and control software to achieve these things.

We are developing middleware that uses container technology to enable the micro-serviceization of software assets that have supported social infrastructure such as power and railways, and the fusion of the latest technologies, such as AI. In addition, we are developing middleware that uses the latest web technology and OSS to realize screens that aim to improve monitoring and maintenance operations.

While systems and operations are becoming more DX-oriented, cyber attacks are also becoming more sophisticated. The targets of attacks are also extending to control systems used for the control of plants and infrastructure, and security measures are becoming a fundamental activity in the operation of control systems. Each customer has its own know-how in the operation of control systems, and appropriate security measures that make the most of the characteristics of the system are required. In order to respond flexibly, we provide one-stop solutions for strengthening security, from understanding the current situation to planning countermeasures. We also provide comprehensive services, including consulting on control security and cyber defense training services.

A centralized environmental information system is essential for the diverse environmental activities being undertaken. EcoAssist is a cloud-based solution that collects various environmental information, such as greenhouse gas emissions, eco-mark product specification ratios, and total material input, from multiple locations, including overseas, and centrally manages it in an environmental information database. We are developing and expanding sales of a system that supports the rapid analysis, improvement, and disclosure of environmental information, with flexibility, versatility, and global compatibility.

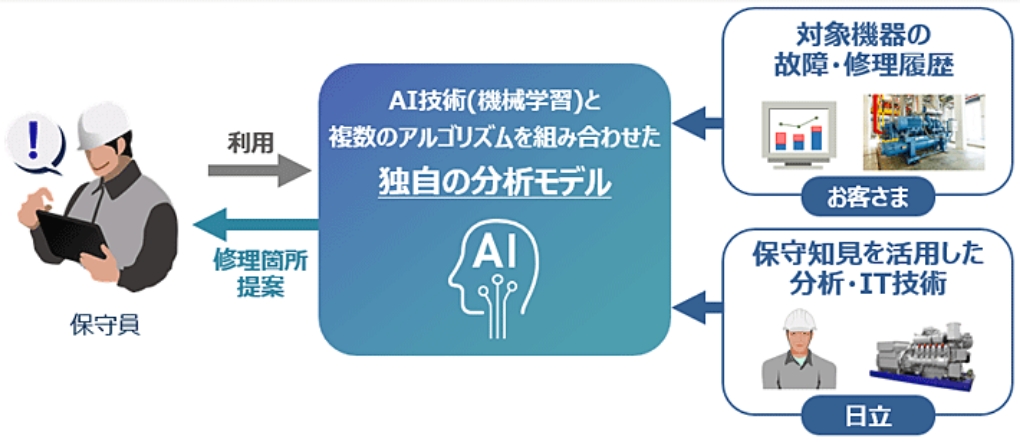

In recent years, the increasing number of parts, more complex structures, and greater specialization of industrial machinery, robots, and social infrastructure equipment in the industrial and distribution fields have made repairs more difficult, and this has become an issue. To address this, Hitachi has developed technologies that automatically recommend the most suitable repair parts and technologies that investigate the cause of a fault through a medical interview, and is promoting the commercialization of these technologies as a repair recommendation service. We are constantly keeping up with the latest technologies, including AI technologies such as deep learning, Bayesian networks, and generative AI, and are developing new areas to promote the AX business.

Control panels and electronic devices that support important social infrastructure are produced in small lots with a wide variety of products due to the various product fields and diversifying product needs. We are working to achieve reliable hardware design across fields for these products and are making daily improvements to realize manufacturing with little change. At the same time, we are also focusing on the development of DX (digitization) technology and core technology, and are pursuing improvements in product quality, cost, and delivery. We aim to solve issues for society as a whole by providing our customers with the knowledge and know-how we have cultivated through this, not only for our own innovation, but also as a service.

As initiatives aimed at achieving carbon neutrality have become more widespread, eco-design has become an important factor in minimizing the environmental impact of products.

Eco-design aims to promote the efficient use of resources throughout the entire life cycle of a product and to reduce waste. In particular, the gcarbon footprinth, which focuses on the amount of carbon dioxide (CO2) emitted throughout the entire life cycle of a product, from raw material procurement to disposal and recycling, is expected to be adopted in many countries and regions in the future, so we are promoting the acquisition of third-party certification and communicating this to the world. In addition, environmental laws and regulations regarding chemical substances contained in products are also being strengthened. In order to comply with regulations, we are investigating and identifying the chemical substances contained in all the parts that make up our products throughout the supply chain, and promoting the elimination of prohibited hazardous substances.

We are working to provide a safe and secure IT environment for our business production activities, and are working on the development of information systems, the introduction of equipment and devices, and stable operation. In the development of business systems, the development process and technology are constantly changing, such as in response to the creation of AI and DX. For this reason, we are constantly working to reform our systems with the aim of updating them to a platform that is resistant to change.

At the same time, cyber attacks are becoming more sophisticated and increasing in number, so strengthening security has become an urgent issue. For this reason, we have built a system for our business systems that uses zero-trust security technology to ensure a high level of security, including safe internet connections and 24-hour automated monitoring of communication logs.

The production line consists of a control panel, printed circuit boards, sheet metal processing and painting of chassis and units, and assembly and wiring lines for mounting these components. At all times, production data (such as input results, quality records, and equipment conditions) is collected through sensing technologies such as RDID tags, cameras, and vibration sensors. By utilizing this data and monitoring operational status, it is possible to predict equipment malfunctions based on equipment alarm history, for example. Furthermore, large-scale production equipment contributes to reducing environmental impact by using AI-based simulation technology to plan input that minimizes energy consumption.

Digital engineering is essential for designing and producing high-quality products with high cost performance. For example, by utilizing simulation technology for heat, noise, structure, strength, and other factors, and performing front-loading quality checks at the design stage, it is possible to minimize the occurrence of rework. Furthermore, the design data obtained through design using such advanced technology is used directly in the production line as digital data. In this way, we are working to DX-ize everything from the design stage to production using advanced technology, and continuing to evolve.

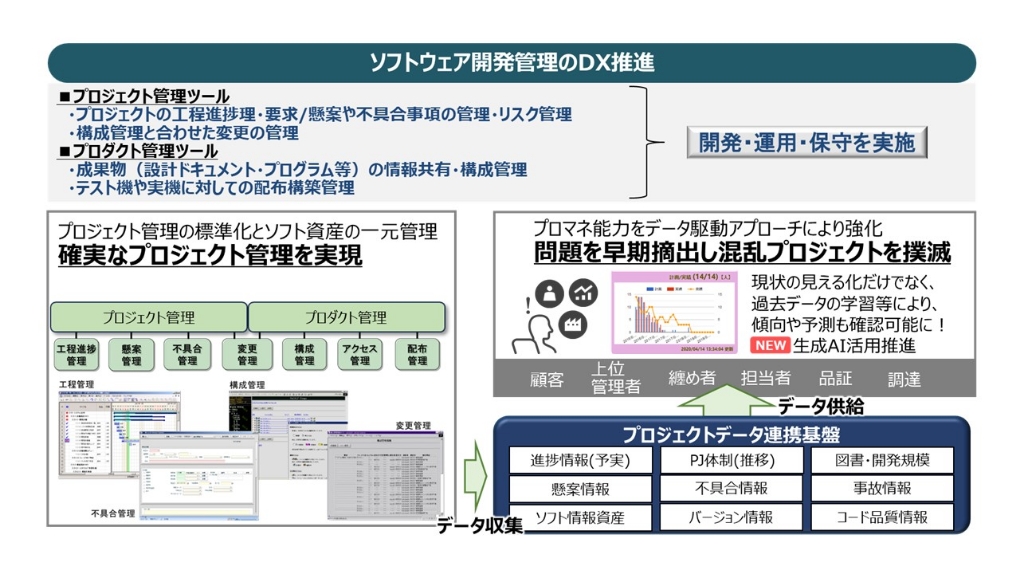

We are working on the design, development and maintenance of business systems (process management, issue management, defect management, deliverable management, etc.) within our offices with the aim of ensuring reliable software development management. Furthermore, we are also promoting the use of AI to not only visualize the current situation, but also to analyze and predict the future based on learning from past data, and we are also working on digital transformation (DX) in software development management.

The Quality Assurance Department always takes the perspective of the customer when looking at products, and not only checks products from the perspective of reliability, performance, maintainability, etc. from the upstream process of product development, but also works with all departments to ensure and further improve quality. We continue to provide our customers with peace of mind and reliability every day by incorporating the operational technology (OT) and advanced inspection technology we have cultivated into the control system products that support society in areas such as power and energy, water environment, railways, and industry.

Control system products that support social infrastructure are required to be of high quality and reliability. These are achieved through system design that takes into account the entire lifecycle, including hardware and software that is designed for 24/7 use, as well as maintenance and servicing. We are working on quality assurance activities in collaboration with all departments, from research and development to design, manufacturing and maintenance services, to support the high quality of our control system products.

As a quality assurance department, we participate in projects from the very beginning of product manufacturing, and always evaluate products from the customer's perspective. In addition to confirming the reliability of components and parts such as servers and communications equipment, we also conduct on-site testing of system shipment inspections and system modifications (hardware modifications) to determine whether they pass or fail, and perform strict shipment inspections before delivery to the customer.

We are involved in quality assurance activities for a wide range of systems, from large-scale systems that support social infrastructure such as train operation management systems and power monitoring and control systems, to operating systems that support systems. We participate in projects from the early stages of development, and work to consistently improve quality right up to the final shipment test.

After delivering the product shipped from the factory to the customer, we will conduct a trial operation by actually connecting it to the actual machine in the plant. Through the trial operation, we will make adjustments to suit the customer's operation. Our field of activity is not limited to Japan, but extends to Asia, Europe, the United States, and other countries around the world.

With the arrival of the IoT and DX eras, there is a demand for products that can be used to create new services that make use of data. We are taking on the challenge of new quality assurance through co-creation with customers, making use of AI and digital solutions, etc.

The Quality Assurance Department comprehensively assesses the quality of the entire system from the customer's perspective, not just the quality of each product manufactured by each design department. We always stand in the customer's shoes and check products from the perspective of functionality, reliability, performance, maintainability, etc. in accordance with system operation, and work to ensure and improve quality. By gaining experience in on-site trial operation and building close relationships with customers, it is possible to understand system operation, and we have the technology to ensure quality from the customer's perspective.

As part of our efforts to maintain and improve quality, we have received ISO certification, an international standard, and have acquired ISO 9001: 2015 certification for all of our production items. In addition, as part of our after-sales service, we have established the Hitachi Control Systems Service Center (HCSSC), which operates 24 hours a day to respond to customer inquiries and provide rapid support.

As we provide a wide range of products, from hardware to software design and development, system integration, maintenance and services, it is necessary to build in high quality at every stage of the process. For this reason, we are developing activities that are involved in the entire system lifecycle.

We provide social infrastructure systems such as power and railway systems to customers around the world, and we also work with our business partners, manufacturing bases and other related parties. The opportunities for quality assurance engineers are expanding throughout Asia, Europe, the United States and the rest of the world.

We believe that using generative AI will have a significant effect on improving productivity and quality in quality assurance work. We are shifting to a way of working where experienced people make the final decision, leaving routine tasks, large-volume data analysis and the extraction of trends and patterns to generative AI. We aim for gWell-beingh.

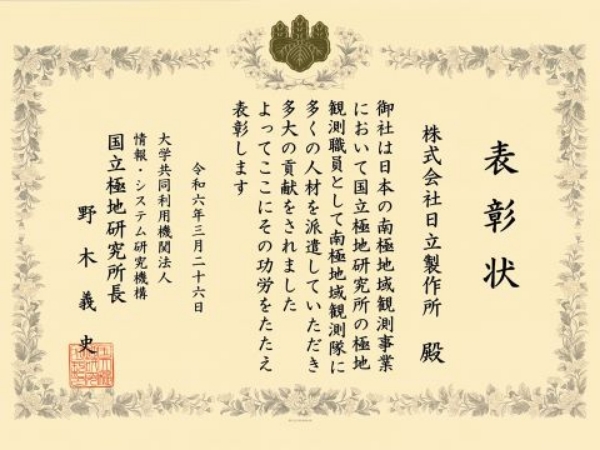

In order to fulfill our corporate social responsibility and to foster young engineers and leaders, we have sent members to the National Institute of Polar Research, which is promoting Antarctic research, and they are contributing to the activities of the Antarctic research team as members of the wintering party. In addition, our products are also installed on the Antarctic research vessel gShiraseh.

We actively participate in external presentations such as the Software Quality Symposium (SQiP Symposium) hosted by the Union of Japanese Scientists and Engineers. In 2019 and 2022, members of the Quality Assurance Department received the gSQiP Best Paper/Report Effective Awardh (practical and immediately useful for quality improvement in the field).