- TOP

- Job Matching Navigator

- Hitachi Industry,Distribution IoT&Robotics SI Solution

Department for Job Matching

Hitachi, Ltd.

In line with the trends of the Fourth Industrial Revolution, the manufacturing industry is facing an urgent need to respond to issues such as high-mix, low-volume production, skills transfer, and automation. Digital solutions utilizing the Internet of Things (IoT) are needed to address these issues. Hitachi is promoting customer co-creation that makes full use of AI and robotics by leveraging the IoT platform "Lumada." We are expanding our social innovation business through digital solutions by merging OT* (operational technology) and advanced IT.

*Operational Technology

(Job title: System Engineer)

We provide system integration services, including IT solutions and the use of AI (artificial intelligence), to solve our customers' problems, from understanding their business to building systems, monitoring operations, and maintaining them. This is an attractive job that allows you to acquire a variety of skills, including technical skills, teamwork, problem-solving skills, and creativity. The main duties of this job are to make proposals to customers and participate in system construction projects, but you may also be involved in formulating customers' business/system concepts and developing applications.

(Job title: Systems Engineer)

Utilizing Hitachi's diverse on-site knowledge, you will be responsible for automation using robotics and transport equipment in production lines and distribution centers, and for building control systems in steel and chemical plants, etc., to realize the sophistication of customers' on-site operations. This is an attractive job that allows you to acquire a variety of skills, including technical skills, teamwork, problem-solving skills, and creativity. The job content mainly involves activities such as proposal activities for customers and participation in system construction projects, and you may also be involved in formulating customers' business/system concepts and developing applications.

(Job title: Design and Development)

Anticipating "societal needs" and working closely with related departments, you will be responsible for designing, developing, and updating competitive solutions and services, creating new value through co-creation with customers. This is a challenging role that requires you to keep abreast of technological advances, such as generative AI, and to understand diversifying needs. Your work will include the development of new solutions and services, and you may also be involved in custom design in response to customer requests.

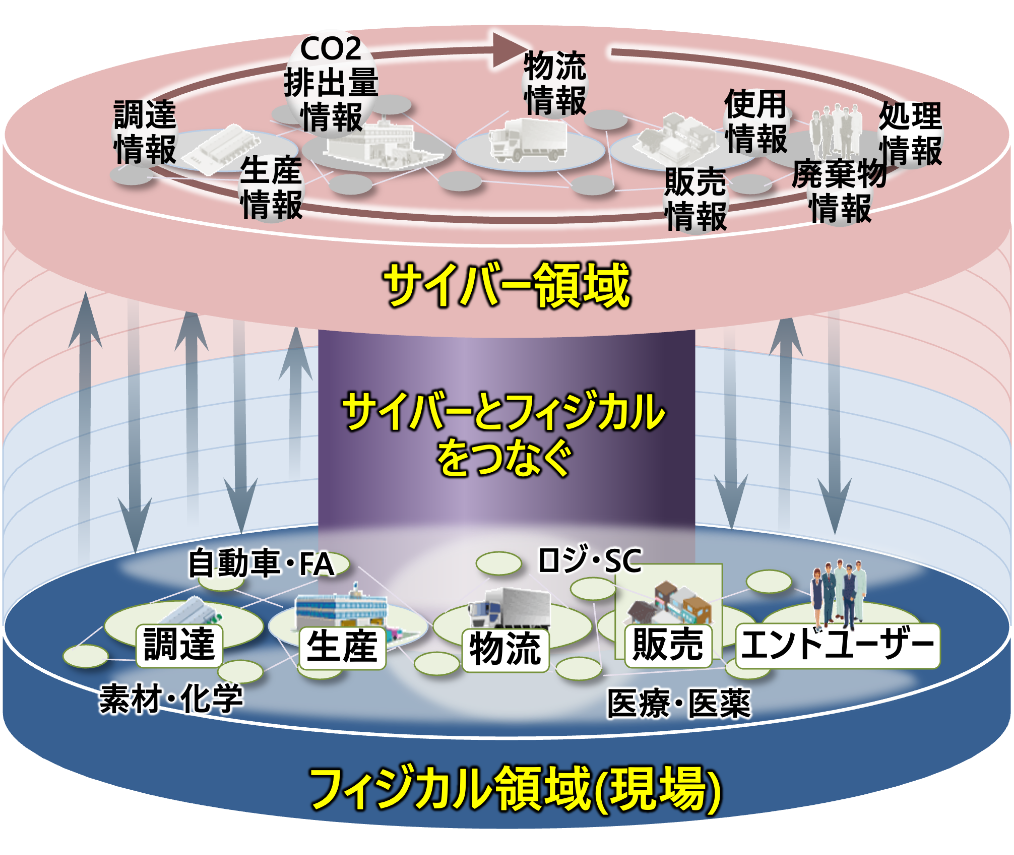

We combine our products, the IoT platform gLumadah, and Robotics SI*1 to connect the cyber and real spaces and realize cyber-physical systems. We provide gTotal Seamless Solutionsh*2 that maximize business value from the customer's management perspective, and contribute to improving social, environmental, and economic value.

*1 Systems Integration

*2 gTotal Seamless Solutionh is a registered trademark of Hitachi, Ltd. in Japan.

This is the total engineering of automation equipment and control systems for manufacturing lines and distribution centers, and the construction of lines that maximize the effects of digital solutions.

Today's manufacturing industry is facing rapid digitization. We are leading the manufacturing industry by providing everything from OT solutions for assembly processes and equipment to IoT analysis of field data. By providing comprehensive support for digital solutions that leverage robotics, the cloud, AI, and image analysis, we aim to deliver the manufacturing of the future that can compete on the world stage.

In recent years, the need for robotic automation in the manufacturing industry has increased rapidly, and the movement toward digital transformation (DX) is also accelerating. We provide OT and IT as a single unit, with robotics SI* at the core, for manufacturing process and logistics automation, helping to improve business value.

*Systems Integration

The manufacturing industry is moving toward next-generation factories, which aim to optimize overall management and factories by connecting core systems, manufacturing execution systems, and FA equipment through a network. FactRiSM supports collaboration with shop-floor equipment and higher-level IT systems, contributing to manufacturing traceability and productivity improvement by leveraging digitized 4M*3 data.

*1 "FactRiSM" is a registered trademark of Hitachi, Ltd. in Japan.

*2 Cyber-physical system

*3 huMan, Machine, Material, Method

In manufacturing plants, the transfer of skills from experienced workers and the transfer of specialized business knowledge are issues. WIGARES uses Hitachi's "structured information integration management technology" to structure, integrate and share information scattered across multiple systems and file servers. This enables the digitization and reuse of business knowledge and aims to automate plant operations and improve business value by automatically providing the necessary information.

*WIGARES is a registered trademark of Hitachi, Ltd. in Japan.

When introducing robots into manufacturing and logistics, it is important to be flexible. In 2021, Hitachi welcomed Kyoto Robotics to the Group and is advancing the intelligence of robots by using high-precision 3D vision sensors and robot controllers.

We aim to create logistics centers that can be operated by a small number of people, using unmanned transport robots such as "Racrew"* and intelligent robots. We will achieve supply chain optimization and advanced transportation and delivery by using AI, simulations, and on-site data, and we will design the facilities, operations, and buildings as a single unit to achieve advanced logistics centers as a whole.

*"Racrew" is a registered trademark of Hitachi Industrial Products Co., Ltd. in Japan.

The transportation of waste products, raw materials, and other production-related parts that come off the production line has traditionally been done by hand, and this heavy labor has been a problem. Hitachi has solved these problems by providing a transport system using the Racrew small unmanned transport robot, contributing to the automation and efficiency of the 24-hour operation of the Suntory Natural Water Kita Alps Shinano-no-mori factory.

Plant operation monitoring relies on decisions based on the experience and knowledge of skilled operators. On the other hand, as it becomes more difficult to find skilled operators due to the declining labor force, there is a need to improve operation and maintenance efficiency to reduce the burden of manual work. The WIGARES integrated information management platform contributes to operational efficiency by digitizing operational knowledge and integrating data scattered across existing systems.

Resonac Oita Industrial Complex became Kurasu Chemical Co., Ltd. in January 2025.

In the manufacturing industry, it is important to strengthen quality control. The manufacturing management system "FactRiSM" introduced by Hitachi to Fuji Machine's Chinese subsidiary has strengthened product traceability and achieved a highly efficient production system by integrating procurement, production and sales. This has made it possible to visualize the progress of the entire business in real time, enabling rapid management decisions.

Hitachi has opened "Automation Square*1 HANEDA" (Automation Square Haneda) in Haneda Innovation City (Ota-ku, Tokyo) and "Automation Square KYOTO" (Automation Square Kyoto) in Kyoto Research Park (Kyoto City, Kyoto Prefecture). We will showcase Hitachi's "Total Seamless Solution," which combines products, OT, and IT to achieve automation and optimization, and uses digital technology to solve problems that arise at the "edge"*2 between the shop floor and management, supply chains, and various industries, through actual equipment displays, videos, and presentations using Lumada as an example, and create opportunities for co-creation with customers and partners.

*1 "Automation Square" is a registered trademark of Hitachi, Ltd. in Japan.

*2 "Kiwa" is a registered trademark of Hitachi, Ltd. in Japan.

We provide consulting services to help our clients realize their business strategies and visions, solve production site problems, formulate various strategies, and help them build and select the most appropriate IoT technologies and solutions.

You will be responsible for managing the schedule, cost, and quality of the projects you propose to clients, and you will lead the projects to success through negotiations with clients and internal coordination.