- Global trends and Hitachi’s efforts

[ English / Japanese ]

In the World Economic Forum, one subject is discussed enthusiastically along with the subject of sustainability.

That subject is “trust.” The importance of trust has been reacknowledged all around the world. In particular, various efforts to ensure trust in supply chains are being undertaken by various countries and organizations.

This article provides background information on trust in supply chains and summarizes our efforts to develop a trust assessment model.

Why is there such a strong need for trust in supply chains now? Let’s look at some events that led up to this.

Over the last several years, product quality issues have attracted attention from news outlets in Japan. For instance, a crack found in the bogie of a Shinkansen railcar received a lot of media coverage and attention.

Similar incidents also occurred in other countries. For example, there was a major incident where an automobile manufacturer tampered with the records from emissions testing of their diesel vehicles and was ordered to pay a huge sum in damage compensation.

In addition to product quality, security has been drawing significant attention in recent years.

There have been incidents that might have led to information leaks or other problems. Some of those incidents were caused by backdoor tools installed on routers or by chips embedded on server motherboards to stage attacks on servers. Such backdoor tools and chips were believed to have been installed at some stage in the supply chain.

| Incident | Dates | Region | Damage | Fallout and the effect on trust |

|---|---|---|---|---|

| Excessive alcohol consumption by co-pilots prior to boarding the aircraft | Nov. 2018 and other dates | UK and Japan | -- | Loss of confidence in flight safety |

| Report of embedded chips that attack server motherboards | Oct. 2018 | US | Confidential information was (allegedly) leaked. | Loss of trust in the companies/products in question |

| Delivery of out-of-specification products for the bogie frames of Shinkansen railcars | Feb. 2018 | Japan | Cracks appeared in the bogie frames of Shinkansen railcars, impacting train operation. | Loss of confidence in the safety of the products/services in question |

| Indiscretions in the emissions testing of diesel vehicles | Sep. 2015 | Germany | The company was fined and required to buy back vehicles that violated regulations, and saw a decline in its market value. | Loss of confidence in the company’s compliance with environmental standards and with laws and regulations |

| Suspected installation of backdoor tools on routers | Apr. 2015 | Various countries | Confidential information was (allegedly) leaked. | Loss of trust in the companies/products in question |

These incidents have a high likelihood of occurring in manufacturing supply chains, but why did they occur?

A possible reason is that the management of supply chains is becoming increasingly difficult. With the globalization of the manufacturing industry, manufacturing sites and suppliers are spreading across countries all across the world. Companies must consider changing the management systems they had established back when their supply chains were still mostly located in their own countries.

The concept of supply chains does not apply only to the manufacturing industry. For example, in the service industry, the management of employees and facilities is considered part of the supply chain. As reported by the media, there have been incidents where public transit drivers or pilots drank excessively prior to work. Such incidents can be attributed to the inadequate management of the supply chain.

As such, problems with supply chains are drawing a lot of attention in all industries. Occurrences of incidents such as those mentioned earlier negatively impact trust in companies as well as trust in their supply chains.

The solution needed in all aspects of society is the development of a trust assessment model.

How are countries around the world actually developing models to assess trust?

In other countries, many standardization groups such as the International Organization of Standardization (ISO) and the National Institute of Standards and Technology (NIST) in the US have begun formulating standards. For example, US think tank Pew Research Center is focusing on studies of online trust. In Europe, Industrie 4.0 and other initiatives are underway to develop models for managing and assessing trust.

The Industrial Internet Consortium (IIC), a global organization that aims to accelerate industrial IoT, provides guidelines to international standardization groups and has also begun formulating guidelines on applying trust assessment models to supply chains and other business elements.

In Japan, the concept of trustworthy supply chains is at the core of the Society 5.0 initiative advocated by the federal government. Based on a request from the Japanese government, the New Energy and Industrial Technology Development Organization (NEDO) is accelerating the Cross-ministerial Strategic Innovation Promotion Program (SIP) with a goal of building trustworthy supply chains.

Concept of a trust chain

One of the themes of the SIP project is achieving cyber and physical security in an IoT society. Industry, government, and academic organizations are working together to develop architecture that ensures trust by using digital technologies.

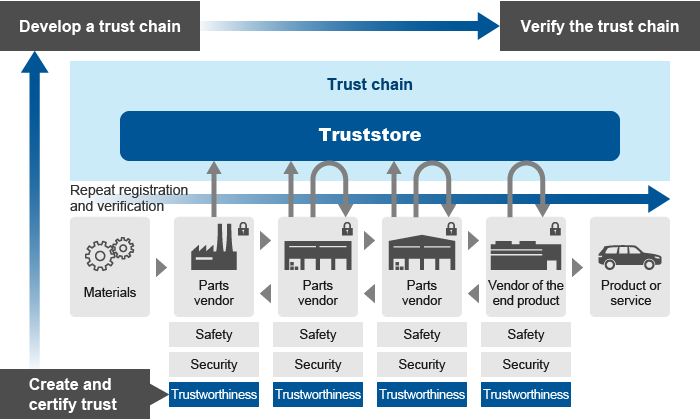

The parties in a supply chain might not know each other. As such, supply chains require a mechanism to record and verify trust information. In the SIP project, such a mechanism is referred to as a trust chain. The SIP project is considering how to develop and consolidate the relevant architecture.

Now that we’ve examined the need for trust chains, the next step is to consider the requirements for building a trust chain.

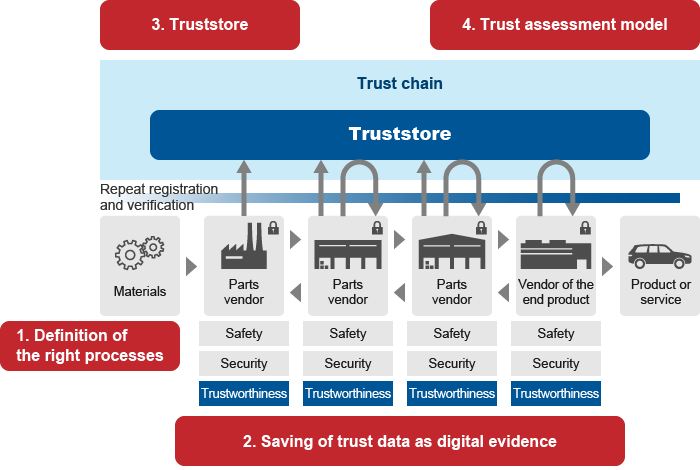

In this section, we will look at four factors needed to build a trust chain, which in turn helps build trust in a supply chain.

Four factors that contribute to ensuring trust in supply chains

First, the right processes for the supply chain must be defined. For example, a manufacturer needs to define information such as the following: (1) the strength of the materials needed to ensure product quality, (2) the procedure for assembling the product in the factory, and (3) the items to be checked during product inspection.

Second, trust data must be saved as digital evidence. Information demonstrating that the product was manufactured according to the right processes must be recorded.

The third factor is a truststore. The saved trust data must be combined into a trust chain to facilitate visualization of trust throughout the entire supply chain.

The fourth and final factor is a trust assessment model. It is essential that a third party be able to determine whether the aforementioned three factors have been properly implemented. Information about how to build trust in the supply chain must be shared among the relevant parties, and assessment must be conducted by using IT infrastructure.

To verify that these four factors have been properly implemented, a trust assessment organization or a similar organization must score each trust chain, issue a certificate, and so on. It is important to note that the building of a trust chain cannot be achieved through the efforts of one company alone. Many different organizations from industry, government, and academia and from various countries must cooperate to move forward with such efforts.

Lastly, let’s look at some of the efforts by Hitachi, Ltd., to build trust in supply chains.

As explained earlier, to build trust chains and trust in supply chains, the cooperation of many different organizations from various countries is essential. As a key member of the IIC and the SIP project, Hitachi, Ltd., has been participating in their activities (as of the writing of this article on February 10, 2021).

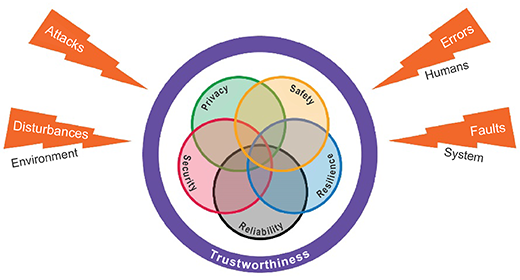

For example, Hitachi is a member of the IIC’s Trustworthiness Task Group and works with other task groups to help build trust in supply chains. We are also actively involved in the formulation of the IIC’s guidelines, the Trustworthiness Framework Foundations.

These guidelines outline a policy for international efforts to build trust in supply chains and promotes a framework that focuses on the following five elements of trust: security, privacy, safety, resilience, and reliability. The guidelines also define compliance and other optional elements of supply chains.

Five elements of trust

Source: Materials published by the Trustworthiness Task Group of the IIC

As a key member of the SIP project to achieve cyber and physical security for an IoT society, Hitachi, Ltd., is working to develop and implement trust chains in society. Specifically, we are working on a PoC to build trust in the COVID-19 countermeasures taken by restaurants. This PoC is conducted jointly with eHills Corporation, which engages in business activities such as the management of building tenants. In this digital trust PoC, we collect, certify, and visualize evidence of the safety measures implemented by restaurants.

Measures taken by restaurants to prevent infection are one of the elements that make up supply chains in the restaurant industry, and evidence of such measures is indispensable for building trust chains. By collecting delivering information about these measures, we can help improve trust in restaurants and provide support for the restaurant industry, which has been hit hard by the COVID-19 pandemic.

The building of trust in supply chains will only become more and more important. Going forward, Hitachi, Ltd., will continue to proactively engage in activities to build trust in supply chains and to deliver information about its activities.

A part of this technology development is executed by

"SIP-CPS (Cross-ministerial Strategic Innovation Promotion Program - Cyber Physical Security) for IoT Society project"

(managed by NEDO) of the SIP, which is advanced by the Cabinet Office.

NEDO: New Energy and Industrial Technology Development Organization

This article was published on March 3rd, 2021.